Products

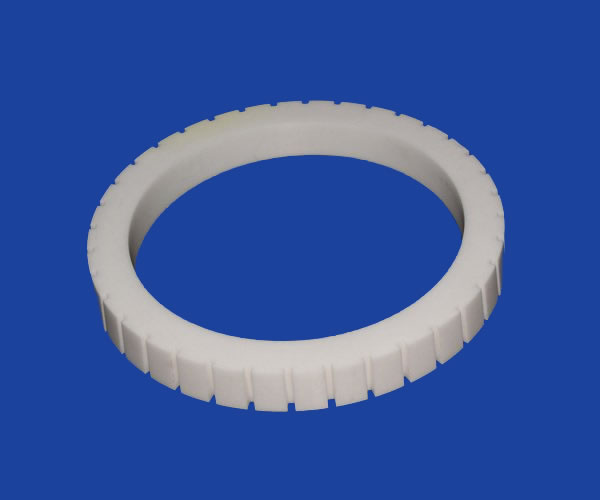

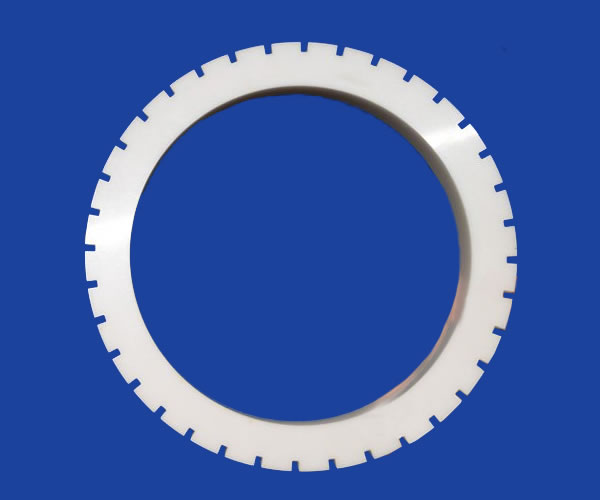

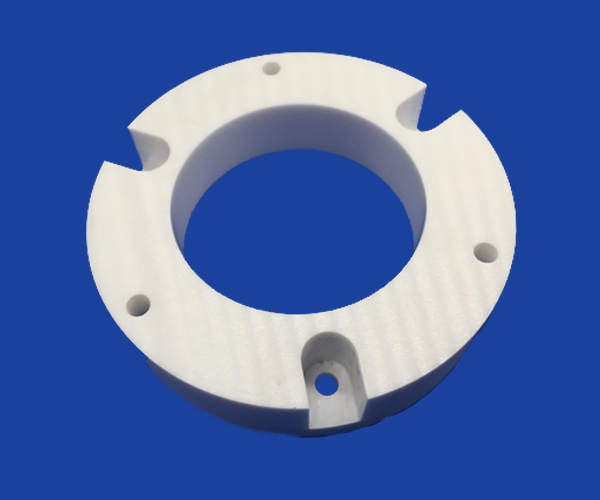

Mechanical Ring Parts Ceramic Seal Rings with Heat Resistant

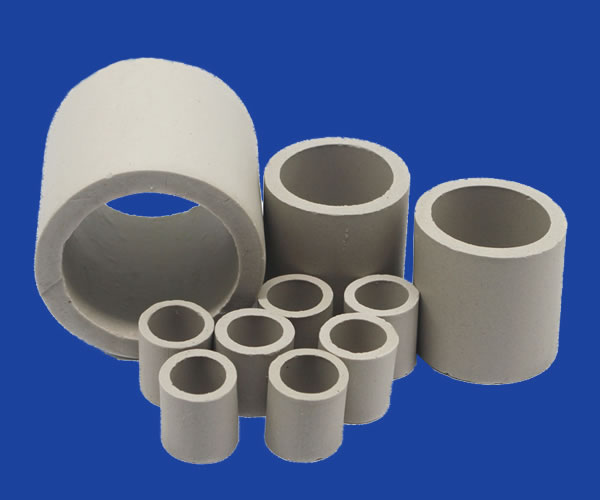

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

SizesCustom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Mechanical Ring Parts Ceramic Seal Rings with Heat Resistant

High resistance ceramic sealing ring by high technology advanced ceramics and refractory temperature: 1750 ℃.High temperature ceramic seal ring are made of the corresponding ceramics (normal type, high purity type, high aluminum type, zirconium type) as raw materials through isostatic pressure, precision processing, sintering and other processes.

High resistance ceramic seal ring is widely used in heat insulation gasket;Kiln masonry lining and expansion joint sealing;High temperature pipe heat insulation;Non-ferrous metal melting groove, groove pad;Observation hole of industrial kiln;Kiln door brick and burner brick;Insulation gaskets for electrical equipment connection;High temperature filtration material;It can replace asbestos products.

C

haracteristics:

low thermal conductivity, low thermal capacity, excellent chemical stability, excellent non-flammability, excellent thermal stability, excellent thermal shock resistance, excellent sound absorption.

Thickness tolerance:

Thickness tolerance of precision gasket: 0.001-0.003 (no tolerance);0.005(±0.001) 0.01-0.03(±0.002)

0.04-0.06(±0.003) 0.07-0.12(±0.004) 0.15-0.18(±0.005) 0.20-0.22(±0.006)

0.25-0.30(±0.007) 0.35(±0.008) 0.40-0.45(±0.009) 0.50-0.60(±0.010)

0.70(±0.012) 0.80-1.00(±0.013) 1.50-2.00(±0.025) 2.50-3.00(±0.035)

Ceramic material composition:

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

Shape :Round , square etc

Available color :black , white , yellowish etc

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm³ | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Thermal shock resistance | △T(℃) | 180-220 | 280-350 | 230-260 | / |

| Tensile strength | MPa | 248 | 250 | / | / |

Precision of manufacture:

Dimensional accuracy: Up to 0.001mm

Smoothness: Highest possible mirror

Concentricity: Up to 0.003mm

Parallelism: Up to 0.002mm

The inner hole tolerance: The minimum 0.005mm

Straight flute: The narrowest 0.1x100mm

The thickness of the size: Minimum to 0.02mm

The screw thread: Minimum internal thread M2

Cylindricity: Up to 0.004mm

The linear tolerance: Up to 0.001mm

The smallest aperture: The minimum 0.07mm

Precision process: CNC maching,grinding,lapping

Surface finish: Glazed,polishing or metallized

Visual quality:

1. No cracks, no dark dots, no contamination and sharp edges;

2. Evenly distributed glaze with very smooth surfaces

Company Introduction

Mingrui ceramic manufacture and provides alumina ceramic components for a wide range of application like Mechanical Equipment, Electronic & Electrical, Oil Drilling, Medical, Chemical Industry etc. According to actual application and customer's requirement, the purities vary from 95%-99.7% and the forming methods will be different. The forming methods applied in our plant include dry pressing, isostatic pressing, injection moulding, extrusion moulding. With experienced engineers and talented workers, we are confident to offer high quality, high precision, complex components for customers worldwide.

| General Characteristics of Materials: | ||||

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium | High | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

EN

EN  CN

CN