Products

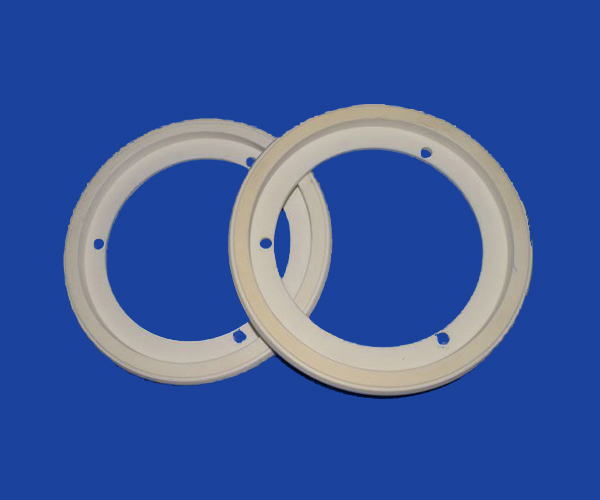

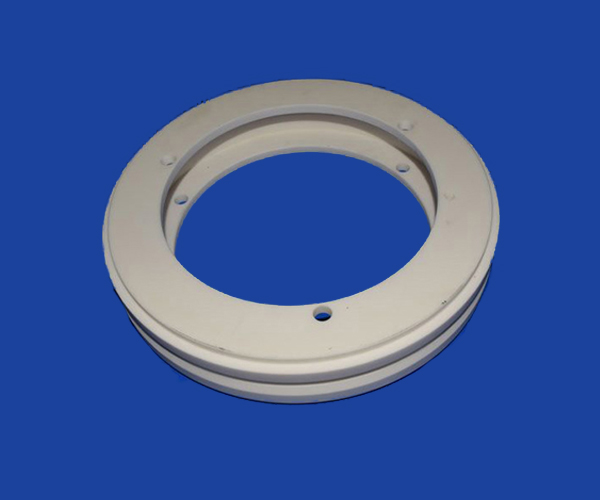

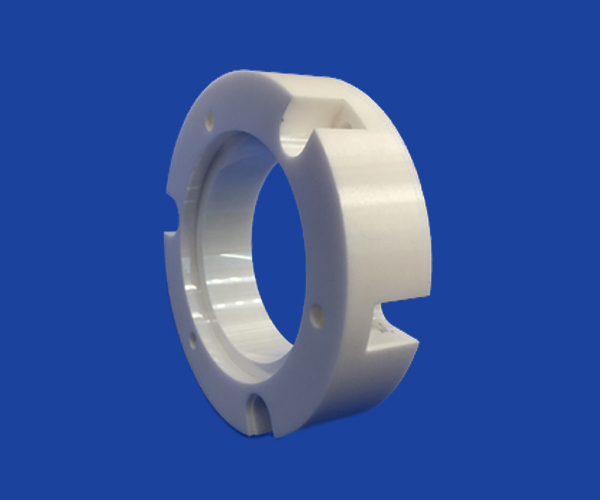

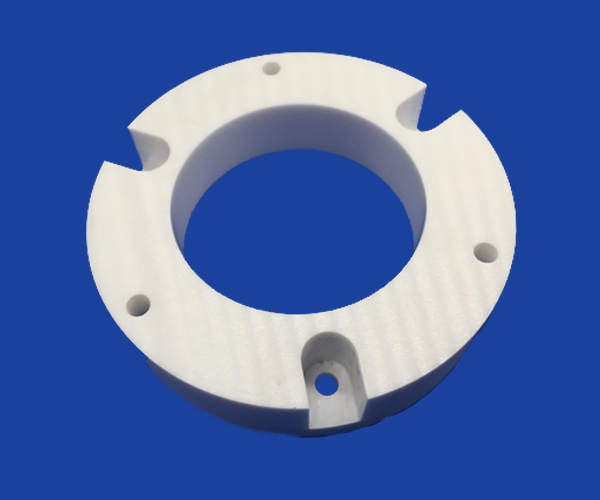

Tooth ceramic gasket ring high temperature high pressure alumina zirconia gasket rings

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Tooth ceramic gasket ring high temperature high pressure alumina zirconia gasket rings

Tooth ceramic gasket ring is a kind of entity ceramic gaskets, first commonly used special precision lathe or milling machine in the two aspects of metallic flat gasket processed into concentric waveform 90 degrees Angle of sawtooth groove, is due to contact with other sealing surface of multiple concentric line contact, so have labyrinth seal effect, according to the different medium and working condition, can choose different ceramic materials.

In most cases, toothed gaskets can be combined with other metal materials for better sealing effect.Refer to metal toothed composite gaskets.Good sealing effect can be achieved without covering sealing layer, but it is easy to damage the flange surface in high-pressure situations.Therefore, it is generally required that the roughness of sealing surface should be more than ra1.6um.

Company Advantage

OEM factory, High quality, Precision processing, Pipelining assembly, 100% QC process, Plentiful stocks, Fast and Safe shipping.

Performance characteristics of toothed ceramic gasket ring:

1. Low pre-tightening force has good sealing effect even under high pressure environment, especially suitable for the occasions of high temperature, high pressure and alternating working conditions. It is an ideal substitute for traditional metal wound gaskets and metal coated gaskets.

2. Pure metal tooth gasket is easy to damage the flange surface, so when replacing the gasket, the sealing surface of the flange should be processed.

3. Use metal materials in combination to achieve better results.

Application scope of tooth cushion:

Toothed gasket is mainly used in petroleum, chemical industry, metallurgy, electric power, shipping, machinery and other industries of medium, high pressure and high temperature pressure vessels, heat exchangers, condensers and pipe flange joint sealing.

The properties of ceramics

· Flexural strength · Chemical resistance · Electrical insulation · Corrosion resistance · Dielectric strength

· Wear resistance · Temperature resistance · Thermal conductivity · High voltage · Hardness...

Ceramic materials

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm³ | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Thermal shock resistance | △T(℃) | 180-220 | 280-350 | 230-260 | / |

| Tensile strength | MPa | 248 | 250 | / | / |

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

| Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface | |

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic sheet,plates,block or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about ceramics parts,please contact our engineers in time >>>

EN

EN  CN

CN