Products

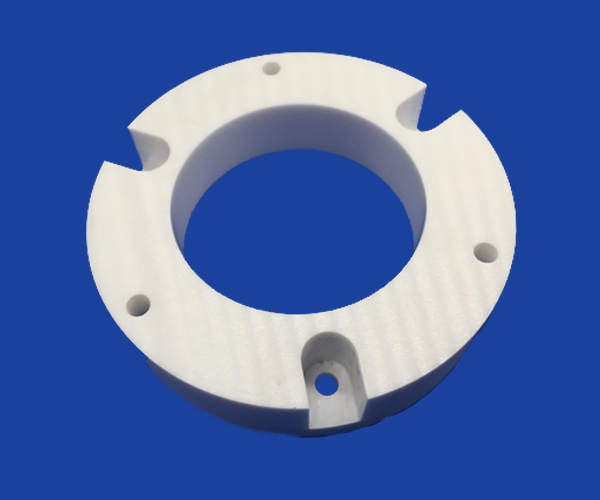

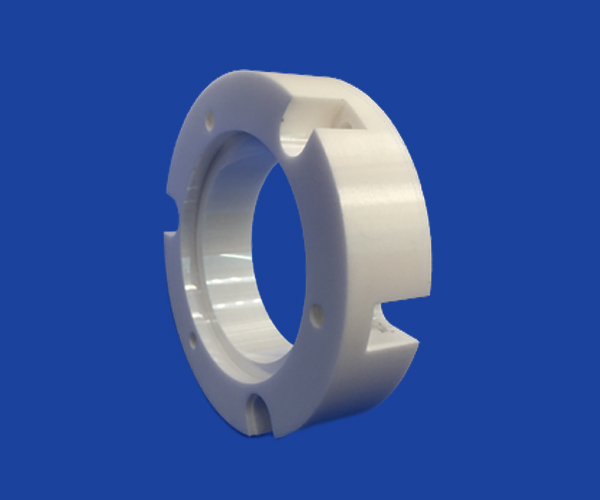

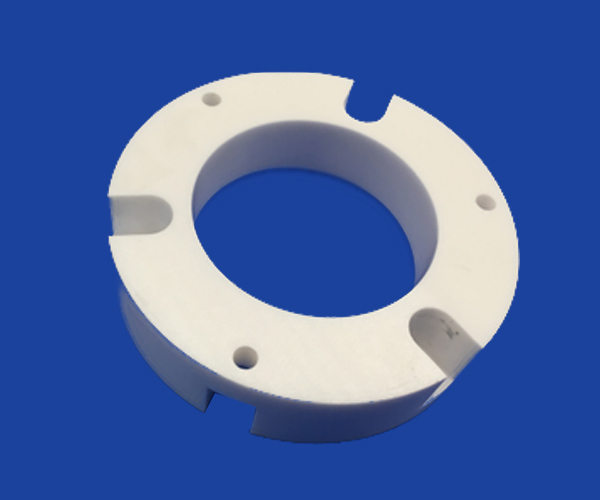

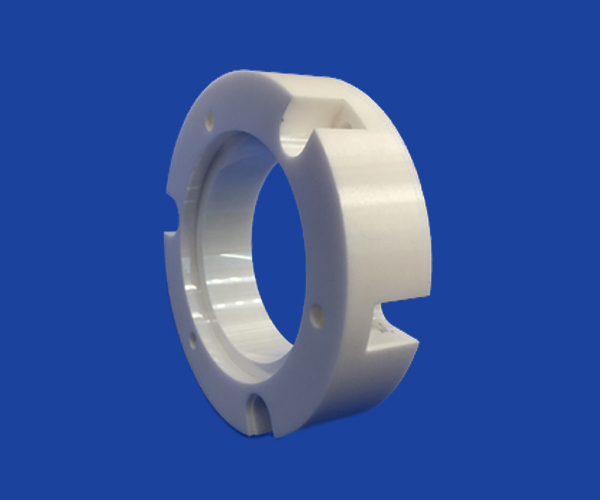

Ceramic Spacer with High Temperature Resistance

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Ceramic Spacer with High Temperature Resistance

Intriduction:

Ceramic spacer is a mechanical seal between two objects often used as a preventive against pressure, corrosion, and corrosion of ceramic tubes as they naturally expand and shrink with heat.Since machined surfaces cannot be perfect, the irregularity can be filled with gaskets.

Ceramic speacer is composed of advanced ceramic materials that have been finely processed as ceramic cutting, punching, grinding, grinding and polishing.

Ceramic materials have high melting point (mostly in above 2000 ℃), and has excellent chemical stability at high temperature;Ceramic thermal conductivity is lower than metal materials, ceramics or good insulation materials.At the same time, the linear expansion coefficient of ceramics is lower than that of metals. When the temperature changes, ceramics have good dimensional stability.

Ceramic washer material composition:

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

Shape :Round , square etc

Available color :black , white , yellowish etc

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm³ | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Thermal shock resistance | △T(℃) | 180-220 | 280-350 | 230-260 | / |

| Tensile strength | MPa | 248 | 250 | / | / |

Ceramic spring spacer (also known as spring gaskets) have a pretension, after being compressed, after recoil.In practical use, due to the characteristics of the screw thread, the nut is easy to rotate along the direction of the screw thread after tightening, resulting in the loosening of the nut.

Early on to solve this problem, spring washers appeared.Spring washer due to the pre-tension, in the nut pressure spring washer, under the action of pre-tension, nut triangle screw buckle and bolt triangle screw buckle on one side, tightly stuck together, in the role of friction, the nut will no longer appear loose.

And ordinary ceramicwasher (also known as circular hole washer or plain washer or ordinary washer), is a support under the pretension of the spring washer, increasing the area under the pretension of the spring washer.

Generally speaking, ceramic spring washer and ordinary washer are used together, the use of ordinary washer alone is not reasonable.

EN

EN  CN

CN