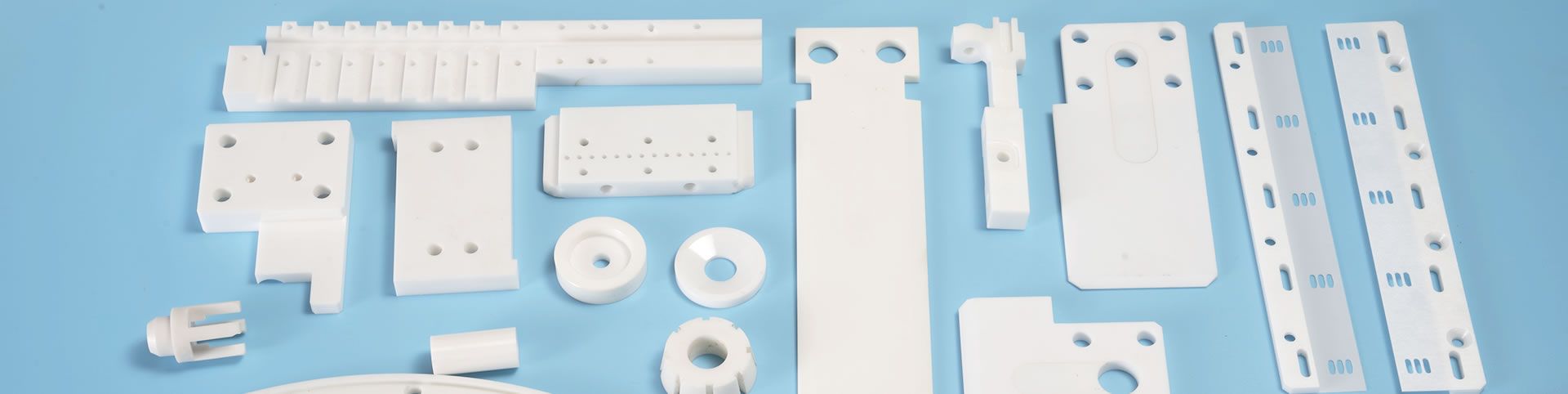

Products

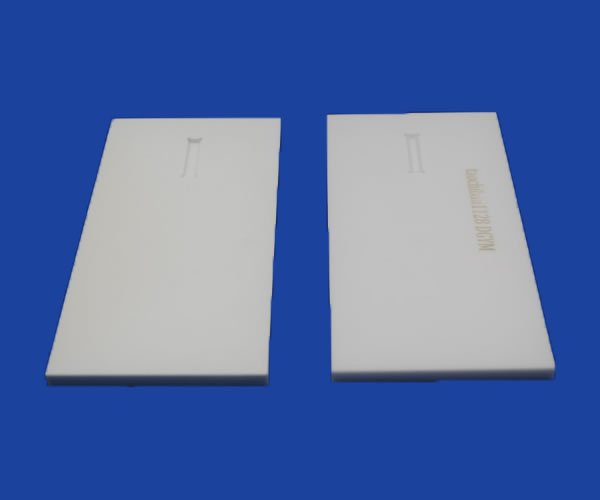

Thermal conductivity ceramic plate

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC

Sizes:Custom according to the requirements

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:thermal conductivity ceramic plate

Can be custom for special sizes and shapes

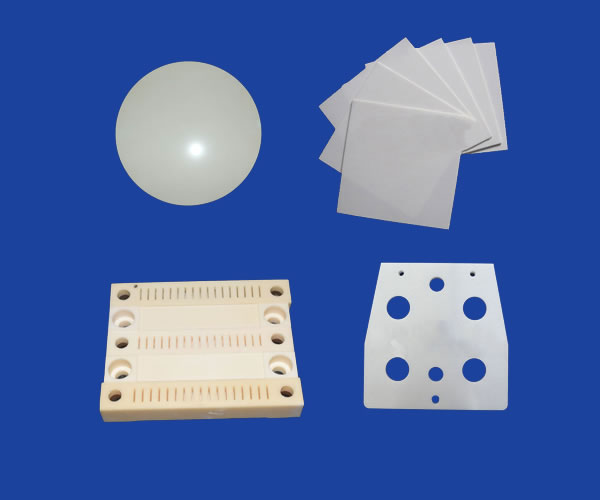

Ceramic plates sheet substrate disc series

thermal conductivity ceramic plate

Thermal conductivity ceramic plate have a good thermal conductivity ability for industry. thermal conductivity ceramic plate have a high hermal conductivity ceramic plate and low hermal conductivity ceramic plate. all of them depend on the raw of the ceramic plate and also depend on the customer applications.

As a pro thermal conductivity ceramic plate manufacturer, we can produce much types thermal conductivity ceramic plate and also offer customized service for our customer need.

The thermal conductivity ceramic plate types produce we can offer:

thermal conductivity ceramic plate

thermal conductivity ceramic disc

thermal conductivity ceramic broad

thermal conductivity ceramic sheet

thermal conductivity ceramic piece

thermal conductivity ceramic pad

others

Dimension :

Maximum length as 450mm; Thinnest thickness as 0.2mm; Widest width as 450mm. we can support to custom other type and sizes of the thermal conductivity ceramic plate.

Shape:

Rectangle, square, circle, semicircle, irregular, customizable

Materials of thermal conductivity ceramic plate we can offer:

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

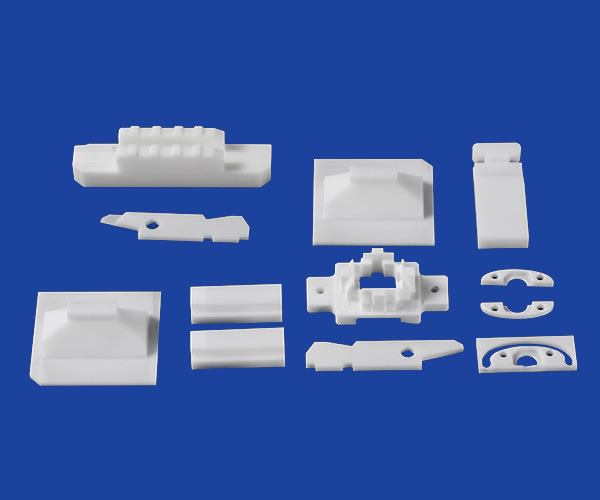

Customization & Machining Service:

As a thermal conductivity ceramic plate manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL.

Our Custom Capabilities:

1.High Purity Martoxid Powder

2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience

3.35000 ㎡workshop, annual output could reach hundred million pieces.

4.All crafts are inspected strictly based on drawings,checked each month.

5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

| Technical reference of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about thermal conductivity ceramic plates,please contact our engineers in time >>>

Tag of the thermal conductivity ceramics

Applications decide thermal conductivity ability

• “High” Thermal Conductivity

• Microelectronics packaging (passive cooling) (e.g. BeO, AlN, diamond)

• Lasers/photonics (e.g. BeO and AlN) (also YAG in solidstate lasers)

• Aero/defense

• “Low” thermal conductivity

• Kiln walls (insulation e.g. RCF, AES)

• Aerospace (insulation e.g. silica aerogel)

• Gas turbines (Thermal Barrier Coatings e.g. 7YSZ)

The need for thermal conductivity ceramics – higher temperatures are behind many material changes

Electronics / semiconductor Higher temperature / increased need for precision Automotive Lower vehicle weight (ICE and xEV) / higher engine temperature Energy / Power Higher temperature / need for improved efficiency Industrial Higher temperature / higher wear environment CPI Higher temperature / higher pressure / high corrosion Medical High corrosion / innovation (new inventions) Military / Defense Higher temperature / lower weight Aerospace Higher temperature / lower weight.

EN

EN  CN

CN