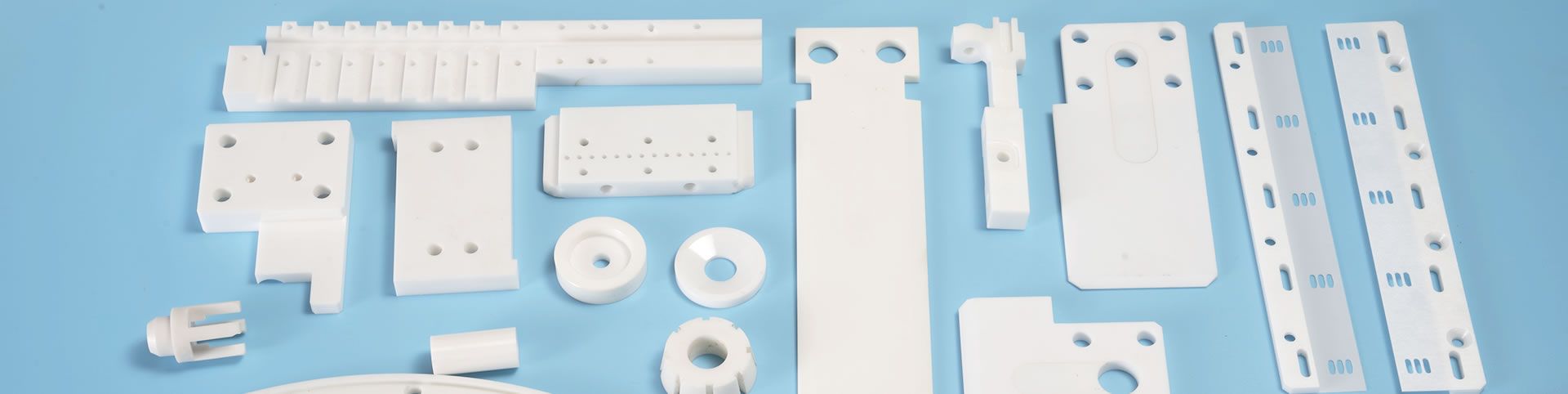

Products

Ceramic connector high temperature higher dielectric strength alumina zirconia ceramic connector blocks

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Max Length/width:450mmThickness:0.2mm...

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

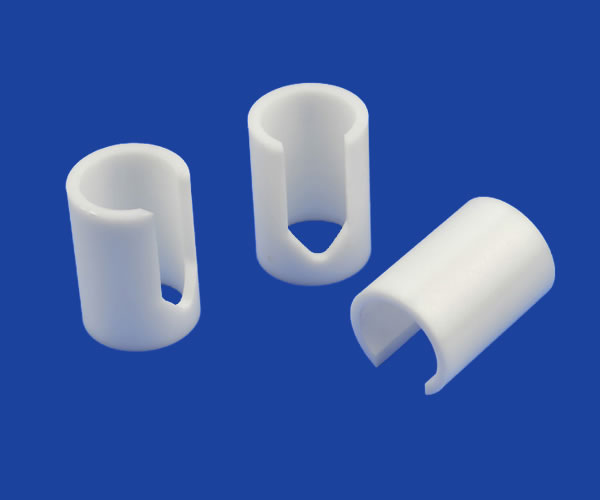

Customized:Can be custom for special sizes and shapes

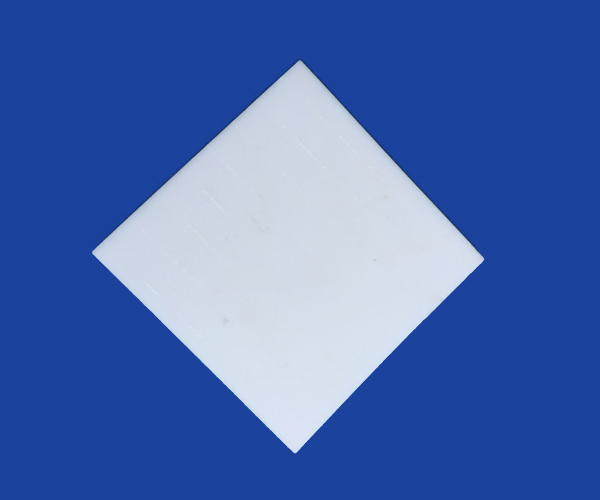

Ceramic plates sheet substrate disc series

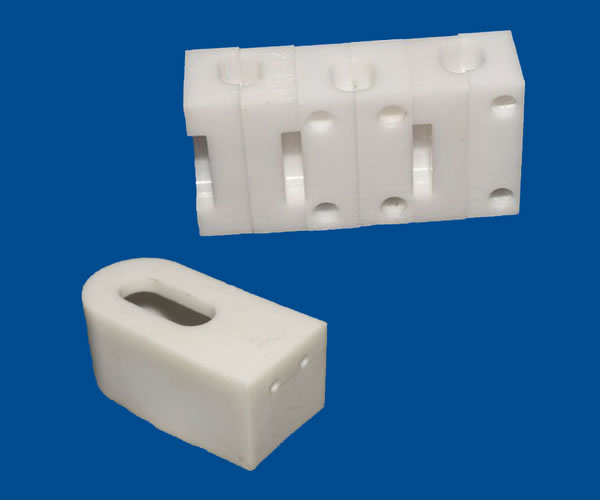

Ceramic Connector High Temperature Higher Dielectric Strength Alumina Zirconia Ceramic Connector Blocks

Ceramic Connector Blocks have a excellent ceramic property with high temperature,higher dielectric strength.

Ceramic Connector Blocks is suitable for the application of continuous temperature as high as 350 degrees c range can have two or three poles and choose the size of Ceramic Connector Blocks the from 21 mm x 18 mm x 15 mm (L x W x H) 53 mm x 30 mm x 23 mm wire size is 1.5 mm to 16.0 mm Ø.Ceramic Connector Blocks used nickel-plated brass inserts and galvanized steel screws to secure the connections.The Ceramic Connector Blocks include M3, M3.5 or M4 screw mounting holes.

Ceramic connector blocks materials:

· 95%--99.99% Alumina(Al2O3) · Zirconia(ZrO2) · Silicon Carbide · Silicon Nitride...

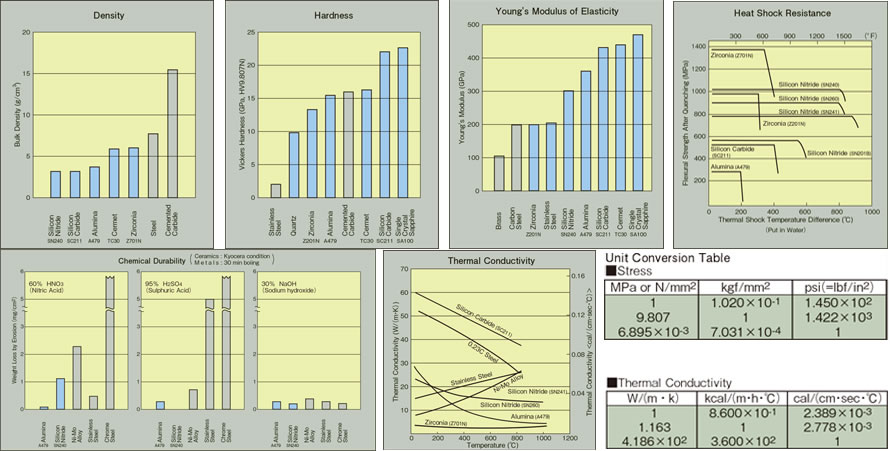

The properties of ceramic connector blocks:

· Flexural strength · Chemical resistance · Electrical insulation · Corrosion resistance · Dielectric strength

· Wear resistance · Temperature resistance · Thermal conductivity · High voltage · Hardness...

Part of ceramic connector blocks parameter:

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm³ | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >10∧16 | >10∧15 | >10∧3 | >10∧13 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Thermal shock resistance | △T(℃) | 180-220 | 280-350 | 230-260 | / |

| Technical reference of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

As a manufacturer of the technical ceramic components,us offer the Customized & Machinable forceramic connector blockswith special specification.·High Precision,Fast Shipping,High Composition (with test report). Get a Quote On Your Customized Ceramic connector Now!!

Lead time:10-20 working days for the mass with free sample of mass ; Minimum order quantity : 1

EN

EN  CN

CN