Products

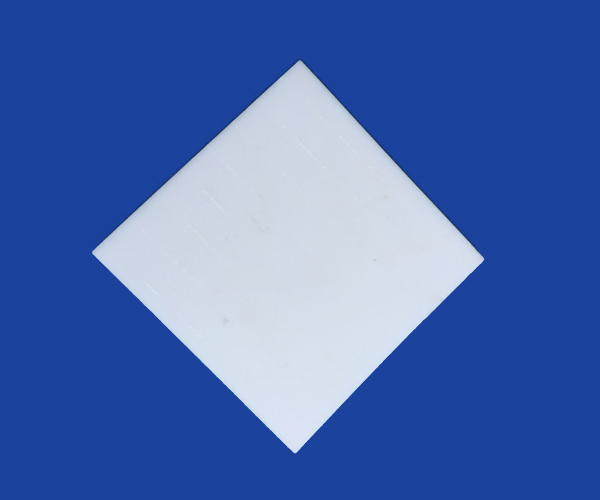

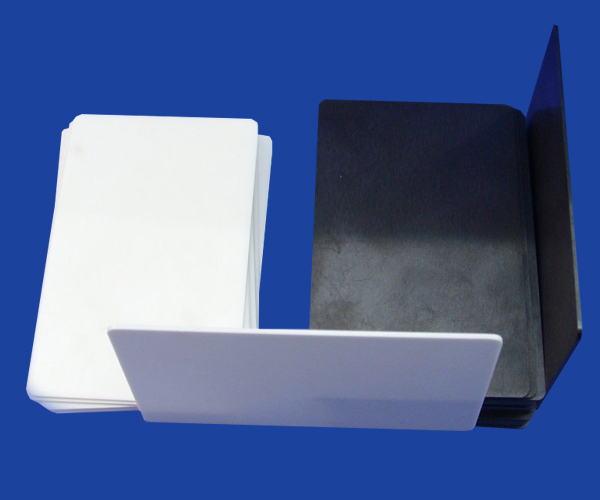

Thin 0.2-15mm Length 10-400mm Width 10-400mm alumina zirconia Ceramic Plate sheet substrate discs

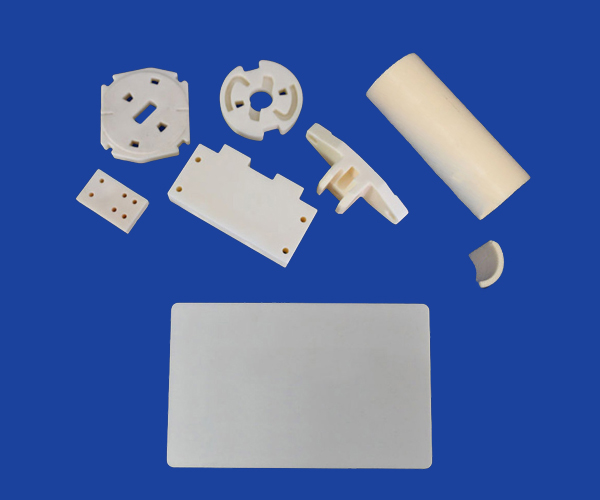

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

SizesMax Length/width:450mmThickness:0.2mm...

Delivery times:2 -25 days(depends on the quantity)

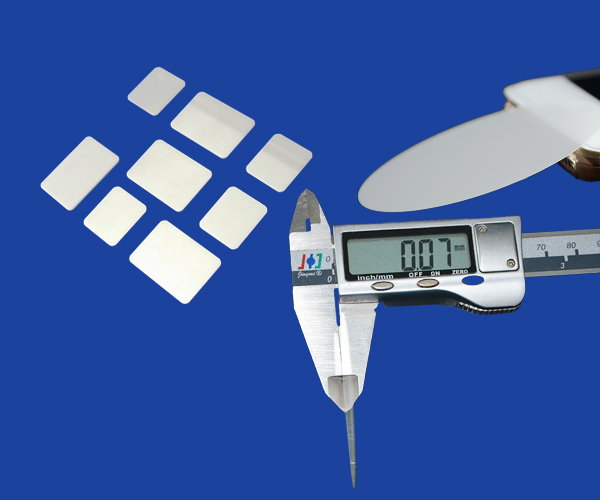

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

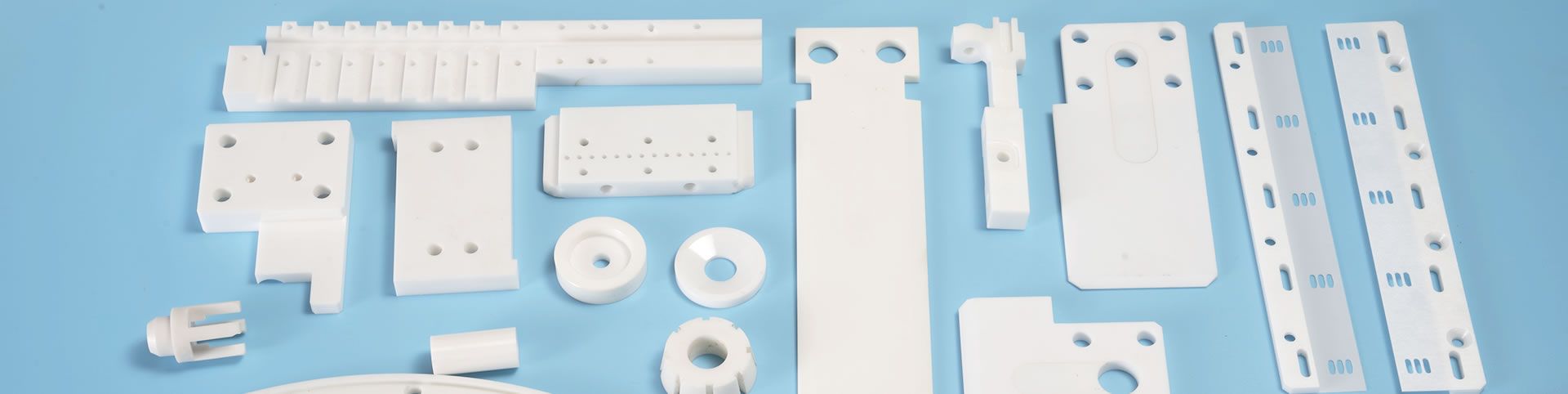

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Thin 0.2-15mm Length 10-400mm Width 10-400mm alumina zirconia Ceramic Plate sheet substrate discs

We have a multi sizes of the ceramic plate sheets in stock, and we also can support to custom the ceramic plates for other sizes.

Our ceramic plate sheet substrate disc made by advance ceramic like 95%-99.99% aluminium oxide ceramics, zircomium oxide ceramic etc which have high temperature resisting, corrosion resistance, chemical resisting, thermal conducitity, insulating etc best performance.

The best-selling sizes are as follows in stock:

Ceramic plates sheet substrate disc series:

| Length | Width | Thickness | Price | Purchase |

| 220mm (8.66in) | 220mm (8.66in) | 5mm (0.2in) | Get the latest price | contact us :[email protected] |

| 216mm (8.5in) | 102mm (4.01in) | 5mm (0.2in) | Get the latest price | contact us :[email protected] |

| 208mm (8.19in) | 110mm (4.33in) | 5mm (0.2in) | Get the latest price | contact us :[email protected] |

| 152mm (6in) | 152mm (6in) | 5mm (0.2in) | Get the latest price | contact us :[email protected] |

| 150mm (5.91in) | 80mm (3.15in) | 4mm (0.16in) | Get the latest price | contact us :[email protected] |

| 107mm (4.21in) | 53mm (2.09in) | 4mm (0.16in) | Get the latest price | contact us :[email protected] |

| 102mm (4in) | 76mm (3in) | 6mm (0.24in) | Get the latest price | contact us :[email protected] |

| 102mm (4in) | 25mm (0.98in) | 1mm (0.04in) | Get the latest price | contact us :[email protected] |

| 90mm (3.54in) | 65mm (2.56in) | 6mm (0.24in) | Get the latest price | contact us :[email protected] |

| 90mm (3.54in) | 45mm (1.77in) | 4mm (0.16in) | Get the latest price | contact us :[email protected] |

| 60mm(2.36in) | 40mm (1.57in) | 1mm (0.04in) | Get the latest price | contact us :[email protected] |

Shape:square, round, oval, flat, strip, porous, irregular, etc

Customization

For the other sizes and shapes, we can offer a customization. please send the details or files to our official e-mail: [email protected]

Applications of alumina plates:

•Alumina substrates plates are hard enough to become armor for personnel or vehicles.

• The corrosion resistivity of alumina plates makes them a great material for chemical industry.

• Used as a material for industrial furnaces due to its ability to maintain its hardness at high temperatures.

• Used for making parts for CVD, ion implants, photolithography, and semiconductor parts.

• In traditional industries, alumina ceramics are ideal for products such as injector tubes, gas nozzles and insulators.

User industries:

Automotive, aviation, space travel

Electrical and thermal insulation

Electronics and sensors

Energy technology, power generation

Environmental technology

Fluid technology

Friction-reduction, wear- and corrosion -protection

High temperature applications

Laboratory technology

Laser technology

Mechanical and chemical process engineering

Metal industry

Optics

Semiconductor processing equipment

Surface treatment

Vacuum technology

Other industries

Specification:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength, Wear Resistance Up To Mohz 9.0; HRA 80-90...

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Thermal conductivity

10. Other excellent property

Main types of ceramic materials for the cermaic plate sheet disc substrates

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

| Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface | |

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic sheet,plates,block or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about ceramics parts,please contact our engineers in time >>>

EN

EN  CN

CN