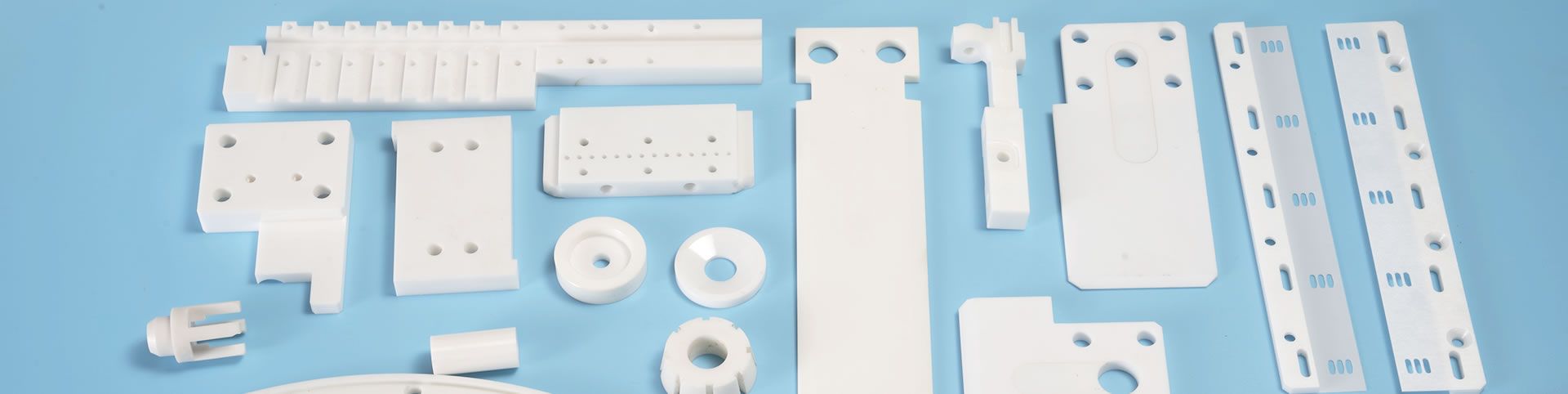

Products

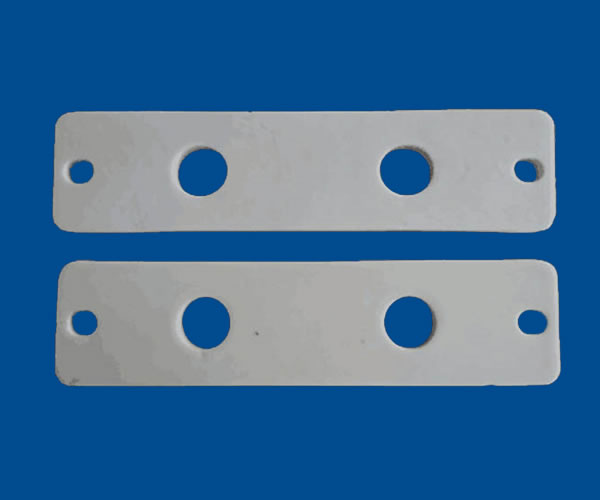

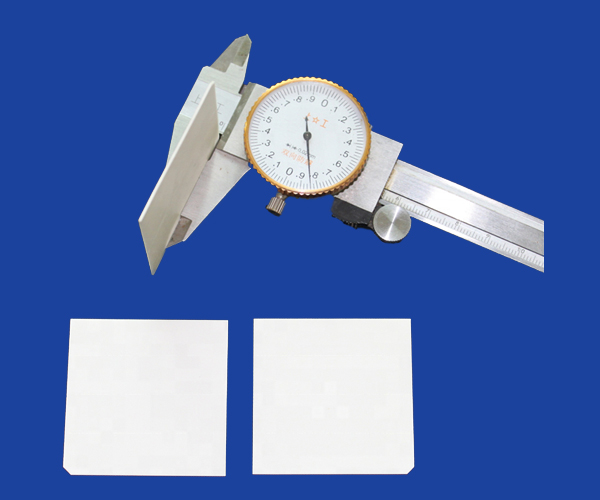

Alumina Ceramic Insulator Plates Machinable Ceramic Sheet For Transistor Heat Sink

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Max Length/width:450mmThickness:0.2mm...

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

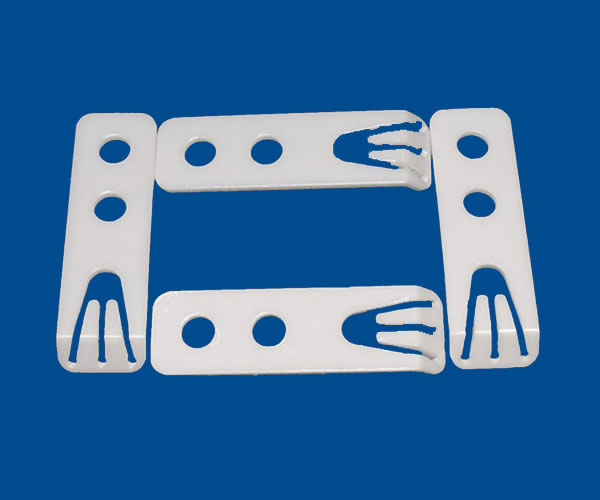

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Alumina Ceramic Insulator Plates Machinable Ceramic Sheet For Transistor Heat Sink

Company Advantage

OEM factory, High quality, Precision processing, Pipelining assembly, 100% QC process, Plentiful stocks, Fast and Safe shipping.

Aluminum ceramic plate is suitable for the IC, MOS transistors, schottky, IGBT and so on need to surface heat source of heat.

Alumina ceramic plates can withstand high temperature and maintain high strength and hardness. Alumina plates also have superb performances in electrical insulation, high chemical resistance and low thermal expansion. We have various sizes of semi finished shapes in stock and are able to conduct custom manufacturing for all kinds of alumina components.

Applications:

• Alumina plates are hard enough to become armor for personnel or vehicles.

• The corrosion resistivity of alumina plates makes them a great material for chemical industry.

• Used as a material for industrial furnaces due to its ability to maintain its hardness at high temperatures.

• Used for making parts for CVD, ion implants, photolithography, and semiconductor parts.

• In traditional industries, alumina ceramics are ideal for products such as injector tubes, gas nozzles and insulators.

Typical properties for common materials of alumina plates

| Composition | UNIT | AL60 | AL95 | AL98 |

| AL2O3 content | % | 96 | 99.5 | 99.8 |

| Color | White | Ivory | Ivory | |

| Tensile strength | Kpsi | 32 | 38 | 36 |

| Flexural strength | Kpsi | 52 | 55 | 54 |

| Compressive strength | Kpsi | 300 | 377 | 350 |

| Density | g/cc | 3.70 | 3.90 | 3.92 |

| Hardness | HV, GPa | 13.8 | 17.2 | 18 |

| Thermal Conductivity | W/(m K) | 25 | 30 | 30 |

| C.O.T.E. | In / In°C (x10^-6) | 7.7 | 7.8 | 7.8 |

| Working temperature | °C | 1500 | 1650 | 1750 |

| Dielectric Constant | 9.5 | 9.7 | 9.8 | |

| Volume Resistivity (25°C) | Ohm-cm | >10^14 | >10^14 | >10^14 |

This chart just demonstrates the typical properties of common alumina materials we use to produce our alumina parts. Please notice that the property for customized alumina parts could vary due to different process. Stanford Advanced Materials could provide alumina products produced under your specified instruction, or do the best to meet customers’ requirements.

Alumina Ceramic Plate Specifications

1. alumina ceramic

2. Very small and very large size can be made

3. High temperature, good abrasive.

Refractory alumina ceramic substrate/ceramic plate is our main product.Misson can supply high quality alumina plates with competitive prices.

Very small and very large sized plates can be made.

Fine grinding can made tight tolerance.

High temperature and abrasive resistance is good

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

| Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface | |

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic bushing or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about ceramics parts,please contact our engineers in time >>>

EN

EN  CN

CN