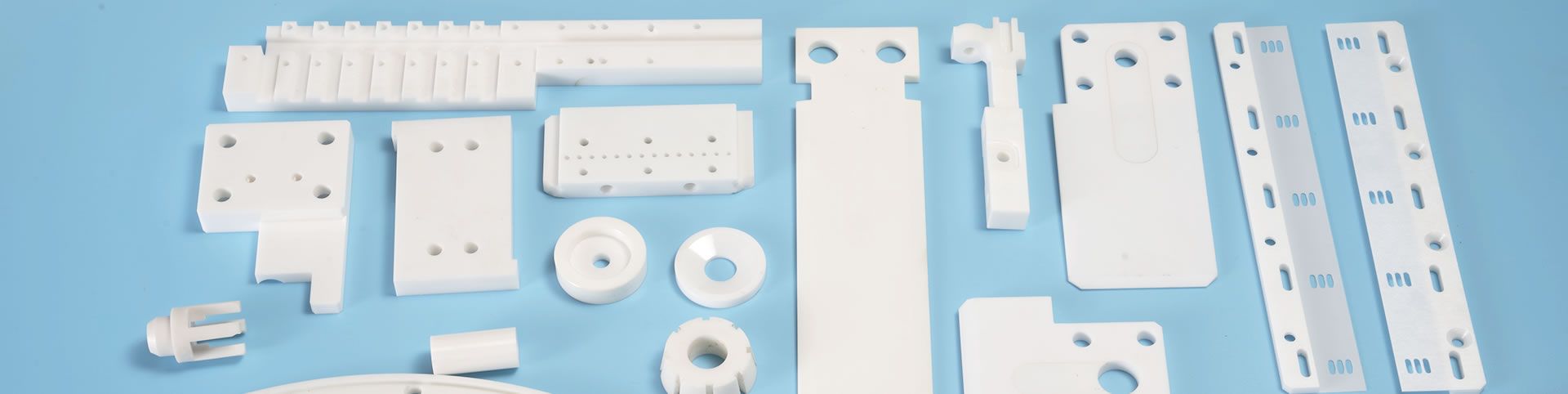

Products

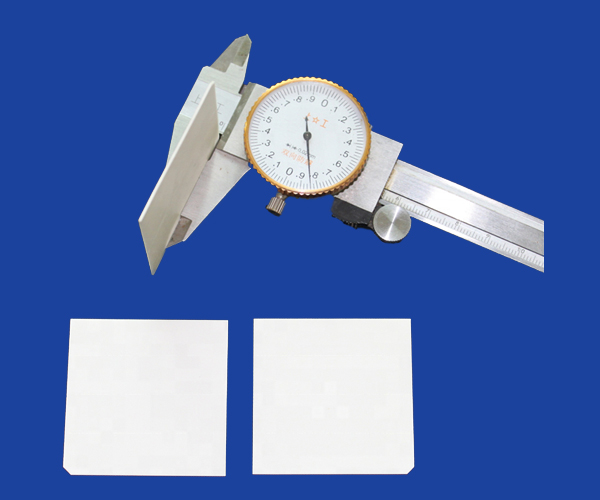

Ceramic substrate sheet multi sizes insulating thermal shock alumina zirconia substrates

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

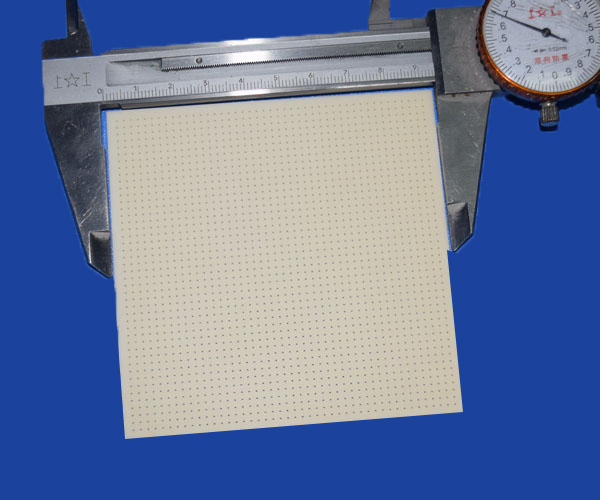

Sizes:Mini-OD: 0.02mm;Max-length: 500mm

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Can be custom for special sizes and shapes

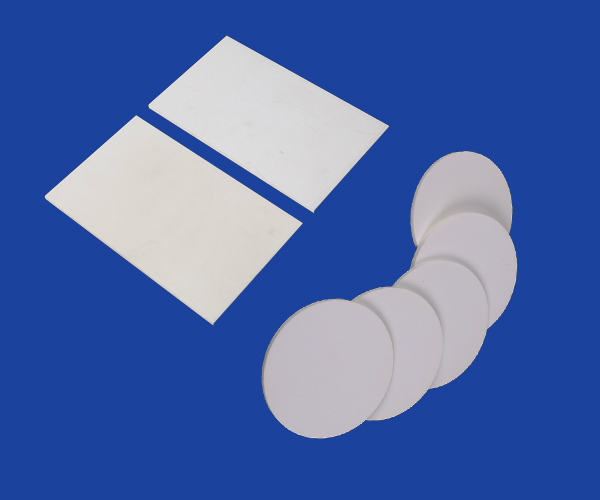

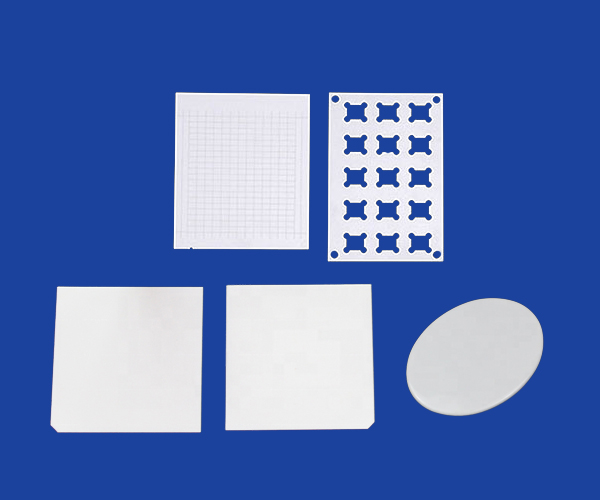

Ceramic plates sheet substrate disc series

Ceramic substrate sheet multi sizes insulating thermal shock alumina zirconia substrates

We are a ceramic substrates manifacturers , we sell and custom a multi sizes ceramic substrates for our customer with multi types of the ceramic materials like 95%-99.99% aluminium oxide ceramics, zircomium oxide ceramic etc which have high temperature resisting, corrosion resistance, chemical resisting, thermal conducitity, insulating etc best performance.

Part of sizes for us produce ceramic substrates like below

| Item | Unit | Ceramic Substrate | |

| Dimension | inch(max) | 5.5"×7.5" | 5.7"×7.8" |

| Tolerance | ±1% NLT:±0.1mm | ±1.5% NLT:±0.1mm | |

| Thickness | mm | 0.25~1.0 | 0.25~1.0 |

| Tolerance | ±10% NLT:±0.04mm | ±10% NLT:±0.04mm | |

| Through hole | mm | Φ0.2~ | Φ0.2~ |

| Tolerance | ±0.6% NLT:±0.05mm | ±0.6% NLT:±0.05mm | |

| Warpage | mm | 0.005/mm | 0.005/mm |

For other sizes of the ceramic substrates please contact us.thanks

and for custom ,please send a details or files to our official e-mail: [email protected] thanks

The shape types of the ceramic substrates

round, oval, square, irregular, etc According to the customer requirement or the drawing.

The main materials of the ceramic substrates:

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

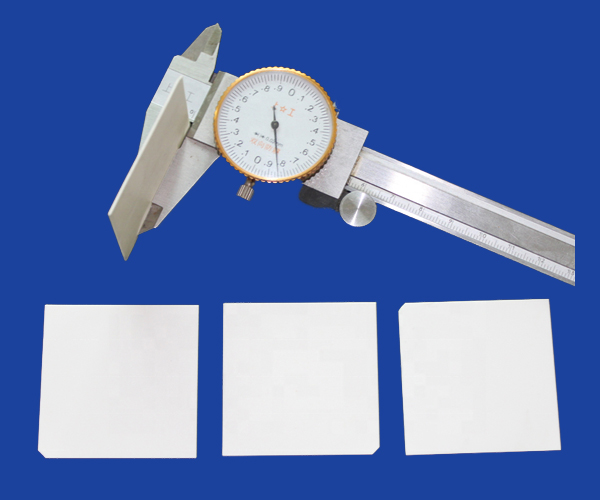

Features of the alumina ceramic substrates

Good smoothness / flatness with less porosity. Excellent in adhesion with thin film and thick film materials.

Less variance in outline, plate thickness, slit pitch, etc.

Minimal warpage, bending, and undulation.

Physical and chemical properties are stable even under a hot environment. Excellent in thermal shock resistance. High thermal conductivity and coefficient of thermal expansion similar to that of silicon.

Superior mechanical strength. Products with higher mechanical strength are also in our lineup.

Excellent resistance against oil and chemical.

Excellent in insulation properties, high dielectric breakdown voltage, high surface resistivity / volume resistivity, and small dielectric constant.

Stable breaking strength, and less variance in shape or dimensions.

The high reflective substrate, especially suitable for optical applications such as LED, is also available.

Applications of the alumina substrates

LED packages, Substrate for chip resistors, HIC substrates for heat dissipation, Power modules, FAX substrates for thermal printer head and other industry

*Various processing is available (thin film metalization, thick film metalization, glaze, etc.)

Features of the silicon nitride ceramic substrate

High Bending Strength about Twice as high as Alumina and Aluminum Nitride (AlN) Substrate

High Thermal Conductivity about Three Times Higher than Alumina and ZTA substrate

Excellent Insulation Properties, High Dielectric Breakdown Voltage, High Surface Resistivity / Volume Resistivity

Coefficient of Thermal Expansion (CTE) Close to Silicon

Applications of the silicon nitride ceramic substrate

Circuit Substrate, Heatsink, Heat Spreader and other industry

Features of the zirconia toughened ceramic substrates

Well controlled surface roughness with homogeneous and fine microstructure

50% higher bending strength than Alumina or AlN substrates.

20% higher thermal conductivity than alumina substrates.

The optical reflectivity is higher than alumina substrates. The substrate with higher reflectivity is also available.

Higher electrical insulation and smaller dielectric constant than alumina substrates.

Applications of the zirconia toughened ceramic substrates

Heat dissipation substrate for automotive, sustainable energy and LED package application and other industry

Other type of ceramic sheet/ plate/ substrate/ piece/ blank

· Ttz: Magnesia Partially Stabilized Zirconia (Zro2) Sheet/ Plate/

· Ytzp: Yttria Partially Stabilized Zirconia (Zro2) Sheet/ Plate/

· Zdy: Yttria Fully Stabilized Zirconia (Zro2) Sheet/ Plate/

· Silicon Carbide Sheet/ Plate/

· Silicon Nitride Sheet/ Plate/

The general specifications service

1. Factory price with a discounts

2. Fast shipment within 24 hours

3. In stocks for hot sales sizes

4. MOQ:1qty

5. Online service

The Custom service

1. Can be custom for special sizes by drawing

2. Can offer a samples within 2 days

3. The delivery time within 20 days after confirmed the order

4. Factory price and Senior ceramic engineer service

5. Online service

Ceramic materials(include but not limited belows)

·95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)...

| Al2O3 | ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN | |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >1014 | 1013-1014 | >1010 | - | 102-106 | >107 | 1012- 1015 | >1014 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

Customization & Machining Service:

As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL.

Our Custom Capabilities:

1.High Purity Martoxid Powder

2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience

3.35000 ㎡workshop, annual output could reach hundred million pieces.

4.All crafts are inspected strictly based on drawings,checked each month.

5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about ceramics parts,please contact our engineers in time >>>

EN

EN  CN

CN