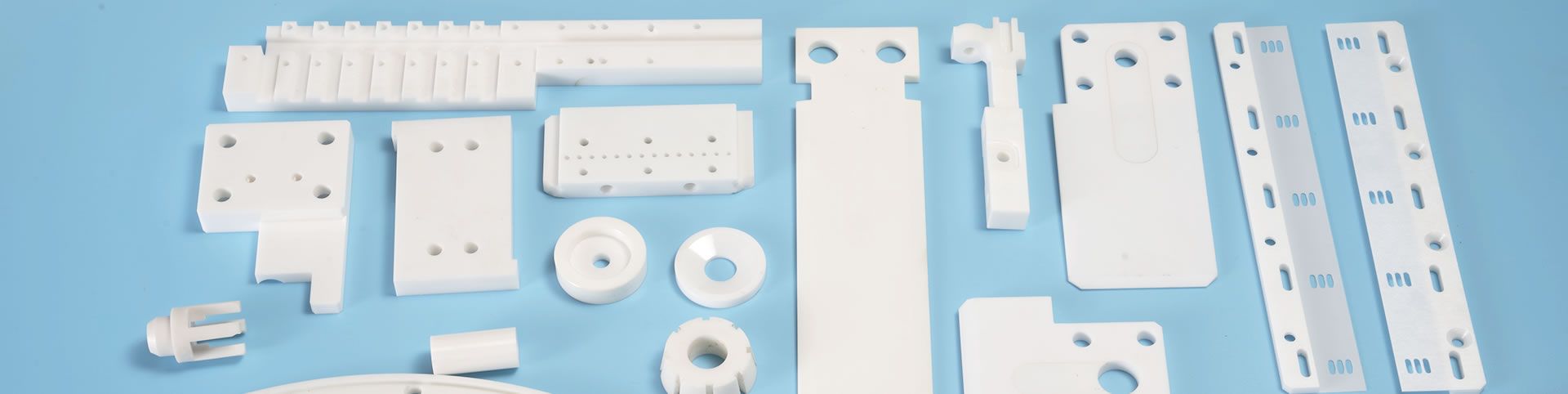

Products

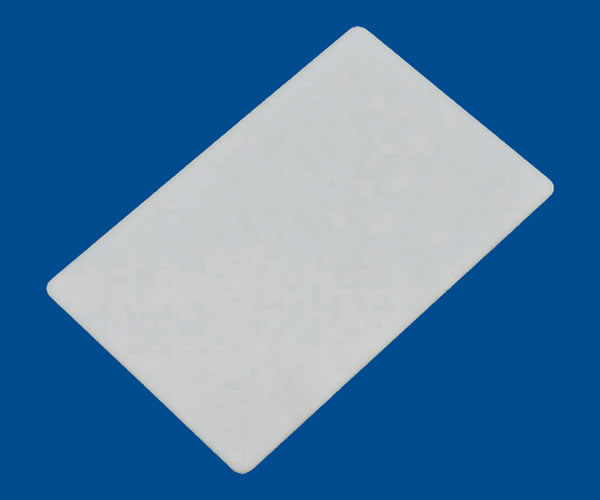

Rectangular Custom High Alumina Ceramic Sheet Industrial Ceramics Strip

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Max Length/width:450mmThickness:0.2mm...

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Rectangular Custom High Alumina Ceramic Sheet Industrial Ceramics Strip

Description

95% alumina ceramic plate is a kind of ceramic part which is made of 95% alumina material. It is white color, wear resistant, acid and alkali resistant, corrosion resistant and high temperature resistant (1600-1700℃). The alumina ceramic chip has the characteristics of good chemical stability, high insulation resistance and strong adsorption capacity, is a kind of excellent electrical insulation and wear-resistance material. The alumina ceramic products are widely used in lamp holder, lamp header, blast nozzle, automobile components and other wear resistance parts.

Technical Data:

| Ceramic Type | Steatite Ceramic | 75% Alumina Ceramic | 85% Alumina Ceramic | 95% Alumina Ceramic | 99% Alumina Ceramic | Zirconia Ceramic |

| Density(g/cm³) | 2.7 | 3.0 | 3.4 | 3.6 | 3.9 | 5.8 |

| Young’s Modulus(Gpa) | 120 | 220 | 250 | 280 | 350 | 205 |

| Max. Working Temperature (℃) | - | 1300 | 1400 | 1500 | 1700 | 850 |

| Expansion (X10-6/°C) (25-800°C) | - | 5-6 | 6-7 | 6.5-8.5 | 6.5-8.5 | 9.5-10.5 |

| Thermal Conductivity (W/(m.R)) | 2.5 | 17 | 18 | 20 | 35 | 2.2 |

| Dielectric Strength (kv/mm) | 18 | 12 | 14 | 16 | 22 | - |

| Water Absorption | - | 5% | <0.2% | <0.2% | <0.1% | <0.1% |

| Bending Strength(Mpa) | 145 | 200 | 240 | 280 | 300 | 900 |

This material has very high hardness, very high stiffness, very good corrosion resistance to chemicals at high temperature, and very high refractoriness or use temperature. They may be used for a variety of electrical, mechanical, and thermal applications. They may be used as setter plates for firing parts in a kiln. The may be used for high temperature furnaces and as high temperature refractory turntables. They may also be used for jewelry or for applications requiring high wear or abrasion resistance. Your imagination is the only limiting factor in the spectrum of possible applications for this component. Be sure to view all photos as they are an integral component of the item description.

The specifications for these components are as follows:

Diameter: Average approximately 14.00" +/-0.010" (381 mm)

Thickness: Average approximately 0.435” +/-0.010" (11 mm )

Please Note:

There are visually discernible differences in any or all of the dimensions. These are not precision technical ceramic components. There is no warp or camber Specification for this item. However they are relatively flat. There may also be “firing” color variations inherent in the material. Some my have minor edge chatter or small edge chips. The thermal shock resistance is not very high so exercise rule of thumb caution. “The larger the piece of material the slower the rate of temperature increase should be applied to the piece.” Heat up slowly to avoid cracking in use.

Specific Gravity or Density: 3.9 g/cm3

Water Absorption or Porosity: 0%

Fusion Temperature or Melting Temperature: 2030 °C or 3686 °F

Maximum Working Temperature: 1800 °C or 3272 °F

Thermal Conductivity: 25 W/m* K

Specific Heat: 0.9 J/g*K

Expansion Coefficient or CTE: 7.5 x 10 E-6 inches/°C

Electrical Resistivity at 20 C: 10 E¬14 Ohm*cm

Electrical resistance at 600 C: 10 E 8 Ohm*cm

Modulus of Elasticity: 44 x 10 E 6 p.s.i. or 350 GPa.

| Product Name | Large Diameter 99.5% High Purity Alumina Ceramic Disk , Alumina Ceramic Plate |

| Material | alumina |

| Color | White, Black , Blue , Yellow |

| Diameter | 5mm - 200mm, And According to drawings |

| Thickness | 0.2-20mm, And According to drawings |

| Surface Roughness | Ra0.1 |

| Torlerance | +/- 0.001mm |

| Lead time: | 15 days |

| Max. working temperature | 1500 -2800 °C |

| Samples | Avaliable |

| Shipping: | Air Express (DHL/UPS/TNT/ FedEx) or Ocean Shipping |

EN

EN  CN

CN