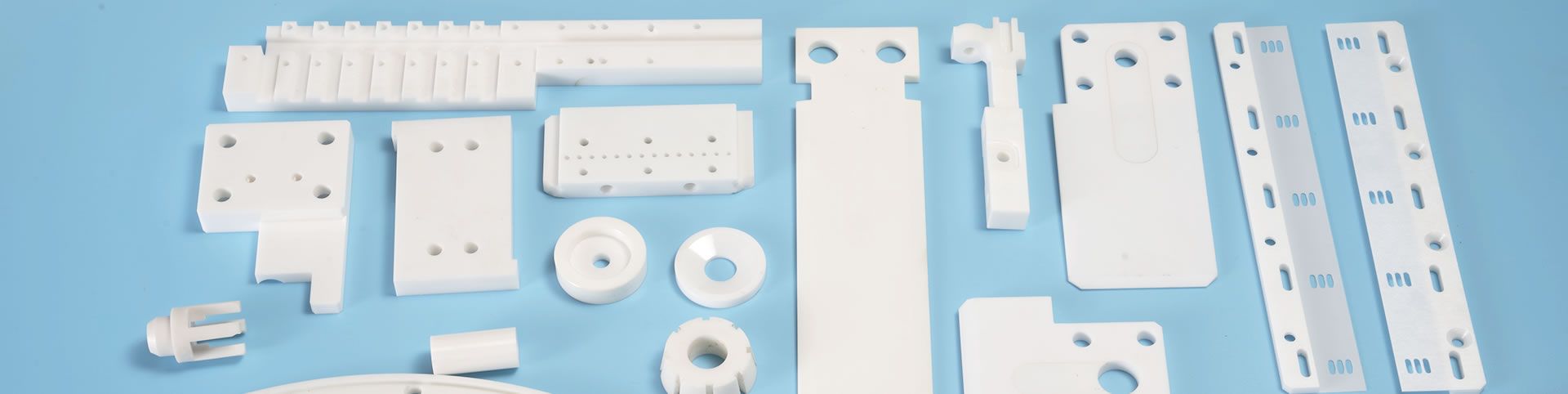

Products

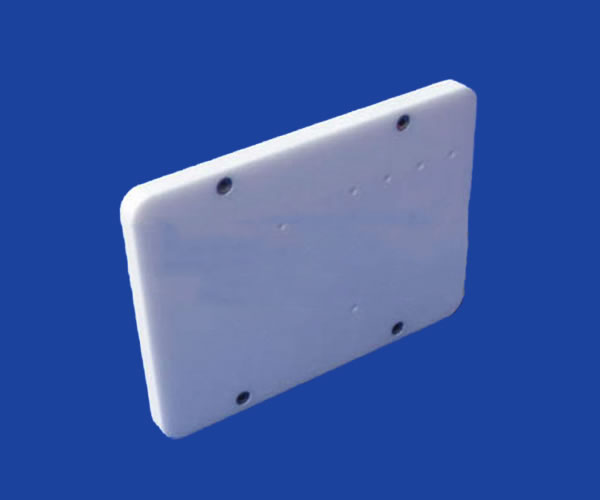

Ceramic wear liners hardness wear / corrosion / high temperature ceramic tile liners

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC

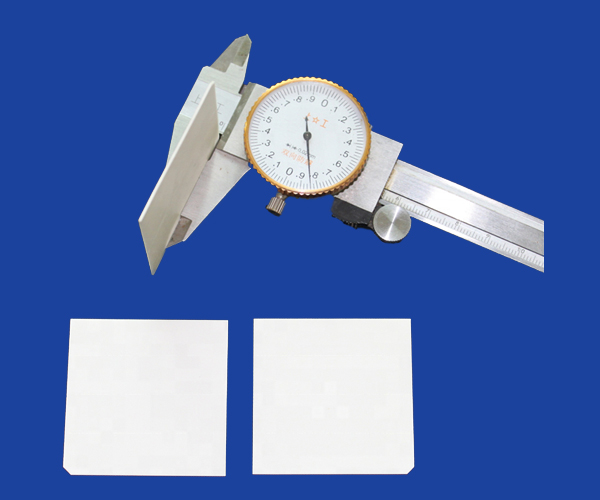

Sizes:Max Length/width:450mmThickness:0.2mm...

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

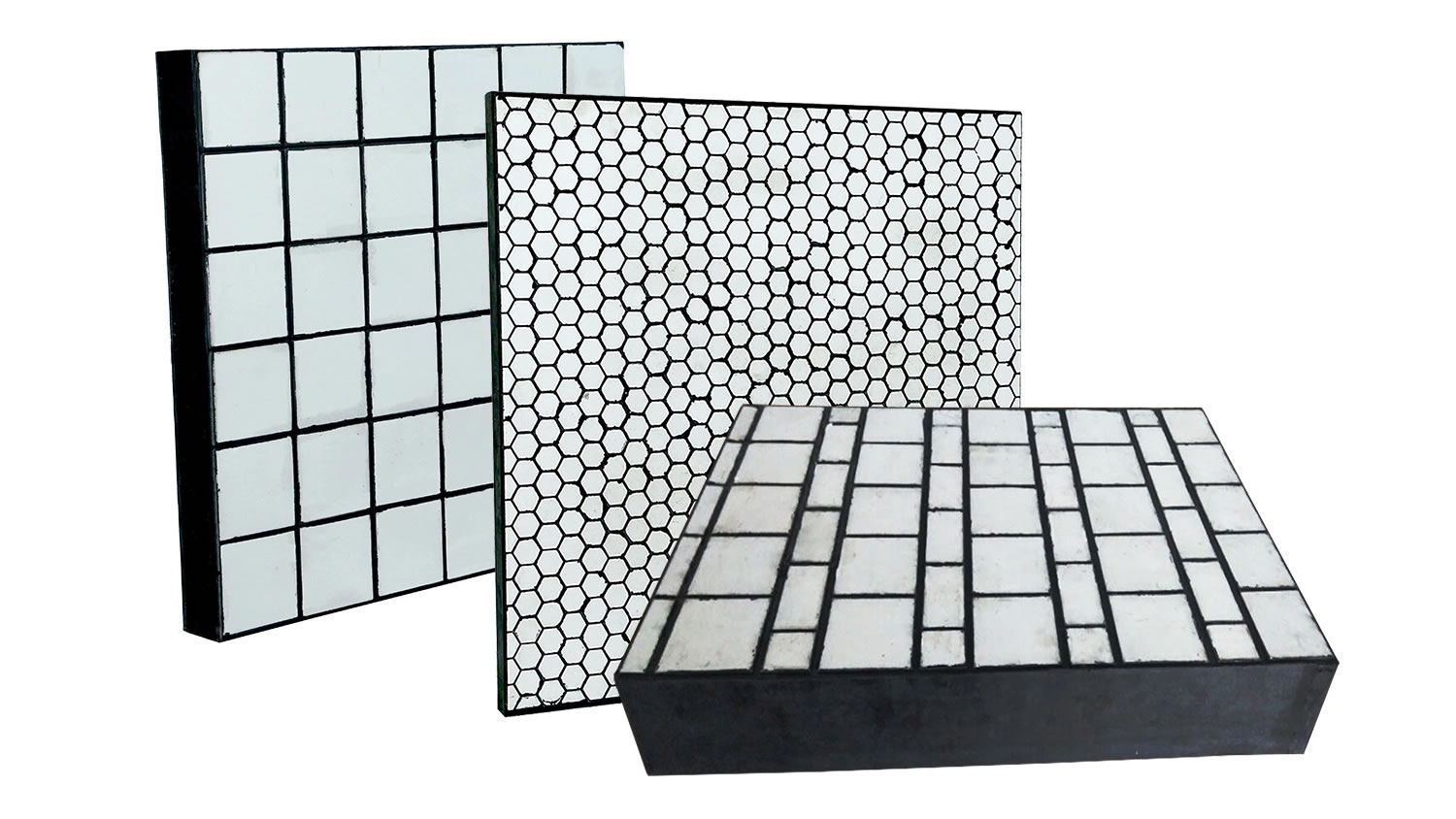

Ceramic Wear Liners Hardness Wear / Corrosion / High Temperature Ceramic Tile Liners

Features and Benefits

· Advanced Hard Ceramic Wearplate

· Easy To Install

· Reduces Noise

· Unsurpassed Resistance

· Impact Resistant

· Smooth Surface

· Longest Wear Life Available

Wear Liner is mainly used in the mining and quarrying industries, where severe abrasion occurs and the angles of impact are low.

Ceramic wear-resistant liner are made of extremely hard ceramic materials that provide unparalleled wear

resistance,excellent Corrosion and High Temperature resistant.

High heat and temperature resistant

The heat ceramic liner have a excellent high heat temperature resistant ability. heat ceramic plate can be used under 2200 ℃ high temperature environment.Coefficient of thermal expansion up to 13* 10∧6 from 20°C- 1000°C. up to 2800°C Melting point.

Wear and hardness and abrasion resistant

The abrasion ceramic liner is better wear and abrasion resistant property than metal. The ceramic hardness (mohs)up to 9, HRA 80-90. Ceramic hardness is not second only to diamond, but far beyond the wear resistance of steel and stainless steel.

Corrosion

Ceramic liner tile material has excellent chemical stability under high temperature, is not easy to oxidize, and has good corrosion resistance to acid, alkali and salt.

Normal size:

500*500*30 300*400*32 500*500*40

316*476*60 188*300*30 300*300*25

Dimension :

·Inside Diameter as small as 0.3 mm

·Inside Diameter tolerance we could make as fine as 0.002mm

·Outside Diameter tolerance as fine as 0.001mm

Additional Information:

·Discounts on large quantities of Ceramic tube

·In stock items will typically ship in a few working days.

·Unit price and estimated ship dates will be calculated when the length and quantity are specified.

·We can be custom / OEM For the liner tube / pipes

Ceramic materials

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)...

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

| Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface | |

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic liner,plates,sheet or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about ceramics parts,please contact our engineers in time >>>

EN

EN  CN

CN