Products

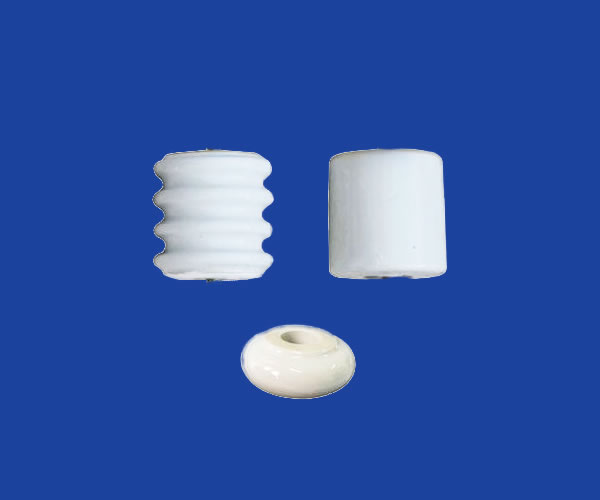

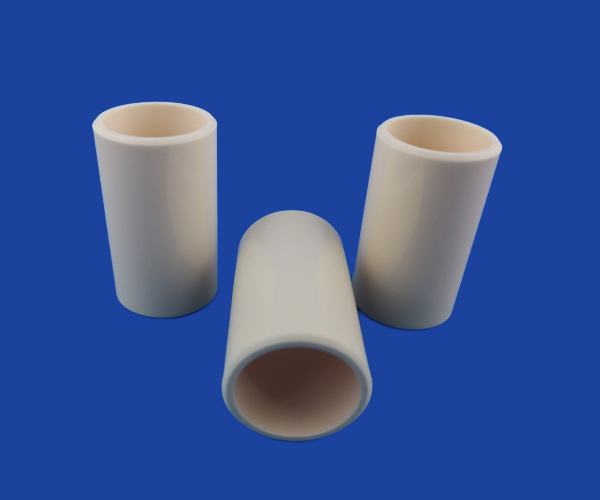

Bushing insulator ceramic bushing excellent high temperature ceramic bushing insulator

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Bushing Insulator Ceramic Bushing Excellent High Temperature Ceramic Bushing Insulator

As a ceramic insulator bushing,mignrui can custom and manufacturing the bushing insulator for the electrials applications with the advance ceramics materials.

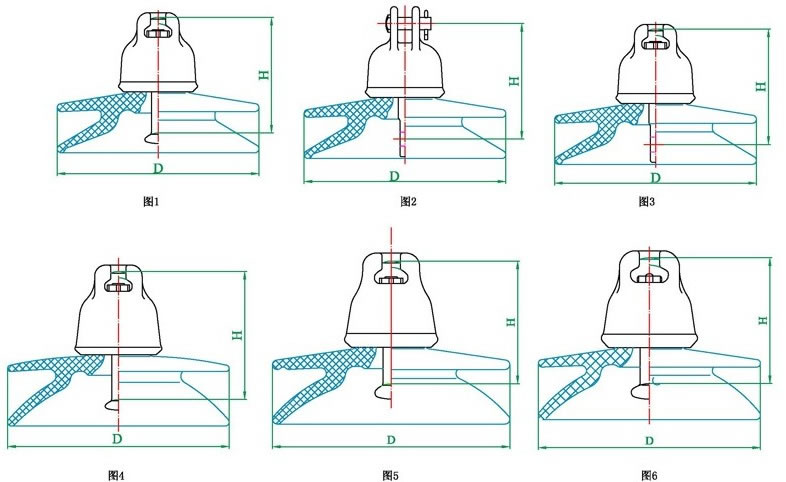

Parts of us manufacturer ceramic insulator bushing available specifications:

| Drawing number | High mm | Disk diameter D mm | Creep distance L mm | Rated electromechanical failure load kN | Tension load kN | Power frequency withstand voltage kV | Power frequency withstand voltage humidity kV | Lightning impulse dry withstand voltage kV | Power frequency breakdown voltage kV | Test voltage to ground kV | 1MHz maximum radio interference voltage μV | Weight kg | ||||||||||||||||||||||||||

| 1 | 160 | 255 | 400 | 70 | 35 | 80 | 42 | 120 | 120 | 10 | 50 | 5.8 | ||||||||||||||||||||||||||

| 1 | 146 | 255 | 400 | 70 | 35 | 80 | 42 | 120 | 120 | 10 | 50 | 5.7 | ||||||||||||||||||||||||||

| 2 | 146 | 255 | 400 | 70 | 35 | 80 | 42 | 120 | 120 | 10 | 50 | 6.1 | ||||||||||||||||||||||||||

| 3 | 146/170 | 255 | 400 | 70 | 35 | 80 | 42 | 120 | 120 | 10 | 50 | 5.9 | ||||||||||||||||||||||||||

| 1 | 160/155 | 280 | 450 | 70 | 35 | 80 | 42 | 120 | 120 | 10 | 50 | 7.1 | ||||||||||||||||||||||||||

| 1 | 146 | 280 | 450 | 70 | 35 | 80 | 42 | 120 | 120 | 10 | 50 | 7.1 | ||||||||||||||||||||||||||

| 4 | 160/155/146 | 255 | 400 | 100 | 50 | 80 | 42 | 120 | 120 | 10 | 50 | 7.1 | ||||||||||||||||||||||||||

| 4 | 160/155 | 280 | 450 | 100 | 50 | 80 | 45 | 120 | 120 | 10 | 50 | 7.7 | ||||||||||||||||||||||||||

| 2 | 160 | 280 | 450 | 100 | 50 | 80 | 45 | 120 | 120 | 10 | 50 | 7.7 | ||||||||||||||||||||||||||

| 4 | 146 | 280 | 450 | 100 | 50 | 80 | 45 | 120 | 120 | 10 | 50 | 7.7 | ||||||||||||||||||||||||||

| 4 | 160/155 | 280 | 450 | 120 | 60 | 80 | 45 | 120 | 120 | 10 | 50 | 8.3 | ||||||||||||||||||||||||||

| 2 | 160 | 280 | 450 | 120 | 60 | 80 | 45 | 120 | 120 | 10 | 50 | 8.3 | ||||||||||||||||||||||||||

| 4 | 146 | 280 | 450 | 120 | 60 | 80 | 45 | 120 | 120 | 10 | 50 | 8.3 | ||||||||||||||||||||||||||

| 5 | 160/155 | 280 | 400 | 160 | 80 | 80 | 45 | 130 | 120 | 10 | 50 | 9.2 | ||||||||||||||||||||||||||

| 5 | 160/155 | 300 | 450 | 160 | 80 | 80 | 45 | 130 | 120 | 10 | 50 | 10.2 | ||||||||||||||||||||||||||

| 5 | 170 | 300 | 450 | 160 | 80 | 80 | 45 | 130 | 120 | 10 | 50 | 10.2 | ||||||||||||||||||||||||||

| 6 | 170 | 300 | 450 | 210 | 105 | 85 | 45 | 130 | 130 | 10 | 50 | 13 | ||||||||||||||||||||||||||

| 6 | 170 | 350 | 525 | 210 | 105 | 90 | 50 | 135 | 130 | 10 | 50 | 13.5 | ||||||||||||||||||||||||||

| 6 | 170 | 350 | 525 | 240 | 120 | 90 | 50 | 135 | 130 | 10 | 50 | 14 | ||||||||||||||||||||||||||

| 6 | 195 | 330 | 480 | 300 | 150 | 85 | 47 | 130 | 130 | 10 | 50 | 15 |

Insulator is a special insulating control which can play an important role in overhead transmission line.In the early years, insulators were mostly used in power poles, which gradually developed into a kind of dish-shaped insulator hanging at one end of the high-type high-voltage wire connecting tower. It is to increase the creepage distance and is usually made of glass or ceramics, which is called insulator.

Delivery:

Custom OEM will be shipped within 15 days after determining the parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the ceramic plates, please contact us or email:[email protected]

Machining process

Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

Mingrui ceramic parts property

· Flexural strength · Chemical resistance · Electrical insulation · Corrosion resistance · Dielectric strength

· Wear resistance · Temperature resistance · Thermal conductivity · High voltage · Hardness...

Ceramic materials

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)...

| Al2O3 | ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN | |

| Physical properties | ||||||||

| Density (g/cm³) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >1014 | 1013-1014 | >1010 | - | 102-106 | >107 | 1012- 1015 | >1014 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL.

Our Custom Capabilities:1.High Purity Martoxid Powder

2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience

3.35000 ㎡workshop, annual output could reach hundred million pieces.

4.All crafts are inspected strictly based on drawings,checked each month.

5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Lead time:within 20 working days after comfirmed order. the samples within 3 days

| Technical reference of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about ceramics parts,please contact our engineers in time>>>

EN

EN  CN

CN