Products

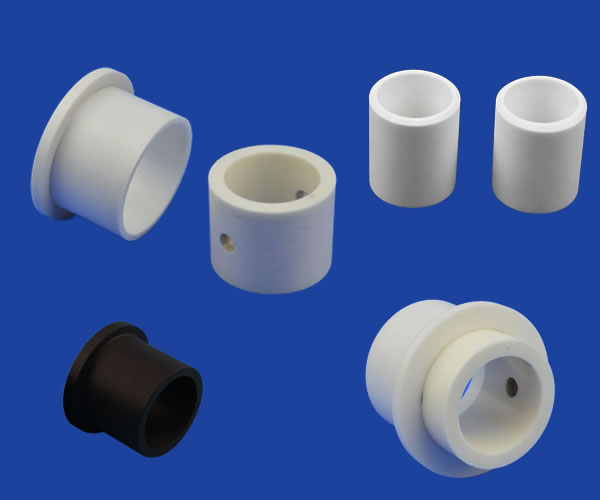

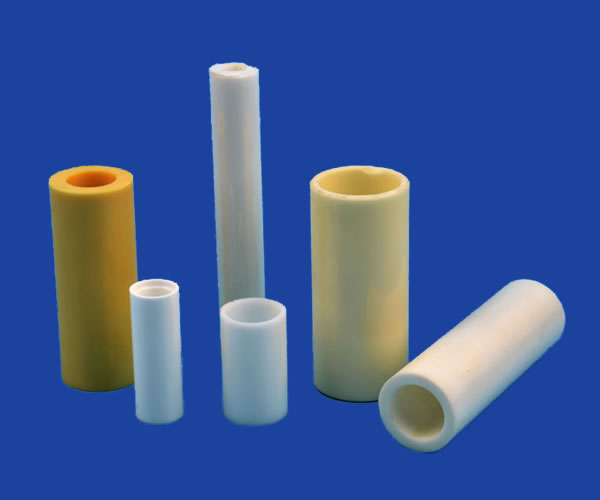

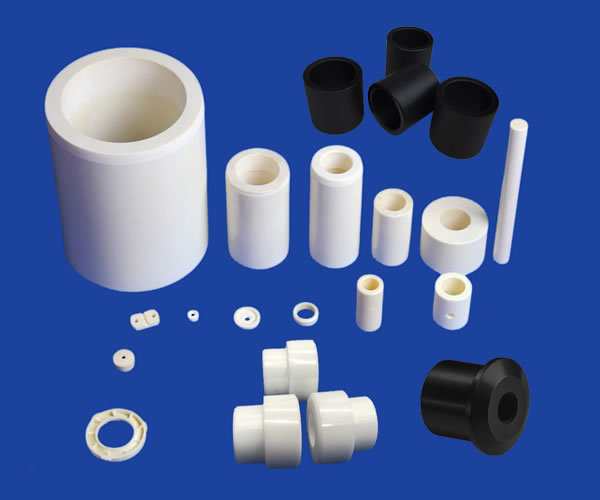

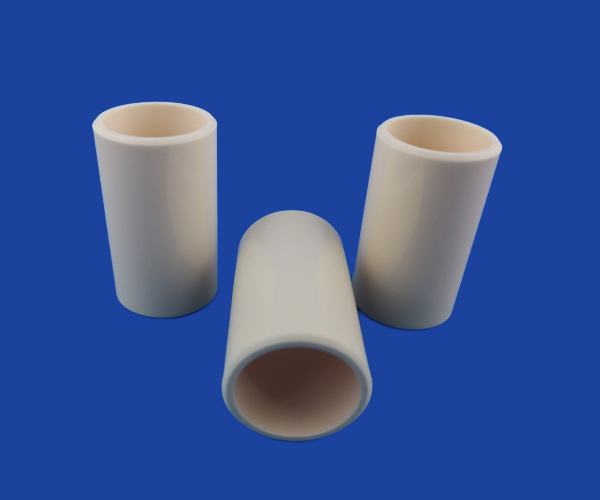

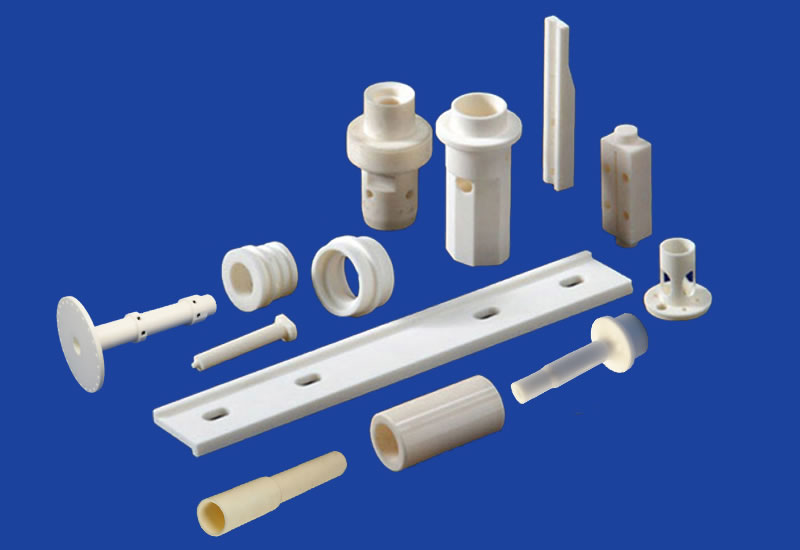

Ceramic bushing wear friction insulator resistance technical ceramic bushing

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Ceramic Bushing Wear Friction Insulator Resistance Ceramic Sleeve

As a ceramic bushings manufacturer,mingrui can offer manufacturing and custom a ragne specification and type of the bushing for industrial applications.

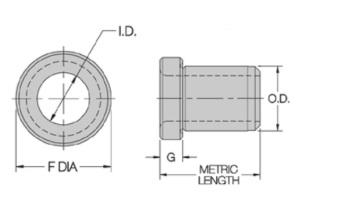

Part of us machining ceramic bushings specifications:

|

Ceramic bushing is a ceramic tube for industry parts. Bushing can be welding, adhesive, inset with the metals use for the industry parts. Due to Ceramic bushing produced by technical ceramic with excellently properties.like a alumina ceramic bushing,zirconia bushing,siliconia bushing.

In the moving parts, because of long-term friction caused by the wear of parts, when the shaft and hole clearance wear to a certain extent must be replaced parts, so the designer in the design of the lower hardness, better wear resistance material for the shaft sleeve or bushing, so as to reduce the wear of the shaft and seat.

Ceramic bushing types and sizes:

Multiple fluted and capped bushings

Re-entrant bushings

Tubular bushings

Barrel and cylindrical bushings

Cable terminations

automotive, aviation, space travel

electrical and thermal insulation

electronics and sensors

energy technology, power generation

environmental technology

fluid technology

friction-reduction, wear- and corrosion -protection

high temperature applications

laboratory technology

laser technology

mechanical and chemical process engineering

metal industry

optics

semiconductor processing equipment

surface treatment

vacuum technology

The function of bushing

The flexibility of the use of bushing is relatively high, it can play a lot of role, generally speaking, bushing is a kind of parts to protect the equipment.The use of bushing can reduce wear, vibration and noise of equipment, and has the effect of anti-corrosion.The use of bushing can also facilitate the maintenance of mechanical equipment, simplify the structure of equipment and manufacturing process.

The function that bushing plays in actual work has a lot to do with its application environment and purpose.In valve applications, bushing is fitted to cover the stem to reduce valve leakage and seal.In the field of bearing application, the use of bushing can reduce the wear between bearing and shaft seat and avoid the increase of clearance between shaft and hole.

Mingrui ceramic parts property

· Flexural strength · Chemical resistance · Electrical insulation · Corrosion resistance · Dielectric strength

· Wear resistance · Temperature resistance · Thermal conductivity · High voltage · Hardness...

Ceramic materials

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)...

As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL.

Our Custom Capabilities:1.High Purity Martoxid Powder

2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience

3.35000 ㎡workshop, annual output could reach hundred million pieces.

4.All crafts are inspected strictly based on drawings,checked each month.

5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Lead time:within 20 working days after comfirmed order. the samples within 3 days

| Technical reference of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about ceramics parts,please contact our engineers in time>>>

EN

EN  CN

CN