The difference between 95 alumina ceramics and steatite ceramics

Mingrui Ceramics is a professional manufacturer of ceramic parts.Aluminais one of the main materials. We often receive inquiries from customers for ceramic parts made of steatite. Knowing the difference between these two materials, Mingrui Ceramics will explain the difference between alumina ceramics and steatite.

To distinguish 95 alumina ceramics from steatite ceramics, we must first understand their differences. So let's take a look at the differences between these two ceramic materials:

1. Different densities

The density of 95 alumina ceramics is 3.7g/cm³, and the density of steatite ceramics is 3.2g/cm³. Their densities are different, that is to say, in the case of the same volume, 95 alumina ceramics are heavier than steatite ceramics. Therefore, by comparing the weight, we can distinguish 95 alumina ceramics from steatite ceramics.

2. the raw materials are different

The main component of 95 alumina ceramics is alumina (Al2O3). Industrial Al2O3 is prepared from bauxite (Al2O3 3H2O) and diaspore. For Al2O3 with high purity requirements, it is generally prepared by chemical methods.

Al2O3 has many isomorphous crystals, more than 10 kinds of which are known at present, there are mainly 3 crystal forms, namely γ-Al2O3, β-Al2O3, α-Al2O3. Among them, the structure is different and the properties are also different, and it is almost completely converted into α-Al2O3 at high temperatures above 1300 °C.

steatite porcelain is made of mineral steatite as the main raw material, adding an appropriate amount of clay and BaTiO3 and other ingredients through the processes of mixing, grinding, molding and high-temperature sintering. The main crystal phase of steatite porcelain is the original enstatite, namely magnesium metasilicate (chemical formula Mgsio3), which is a high-frequency structural ceramic with excellent electrical properties and low price, and is often used as an insulating component in high-frequency equipment.

3. Different application fields

95 alumina ceramics have the advantages of high hardness, good wear resistance, high toughness, low friction coefficient and good corrosion resistance, so alumina ceramics are widely used in machine seals, semiconductors, photovoltaic equipment, ceramic bearings , car engine parts, etc.

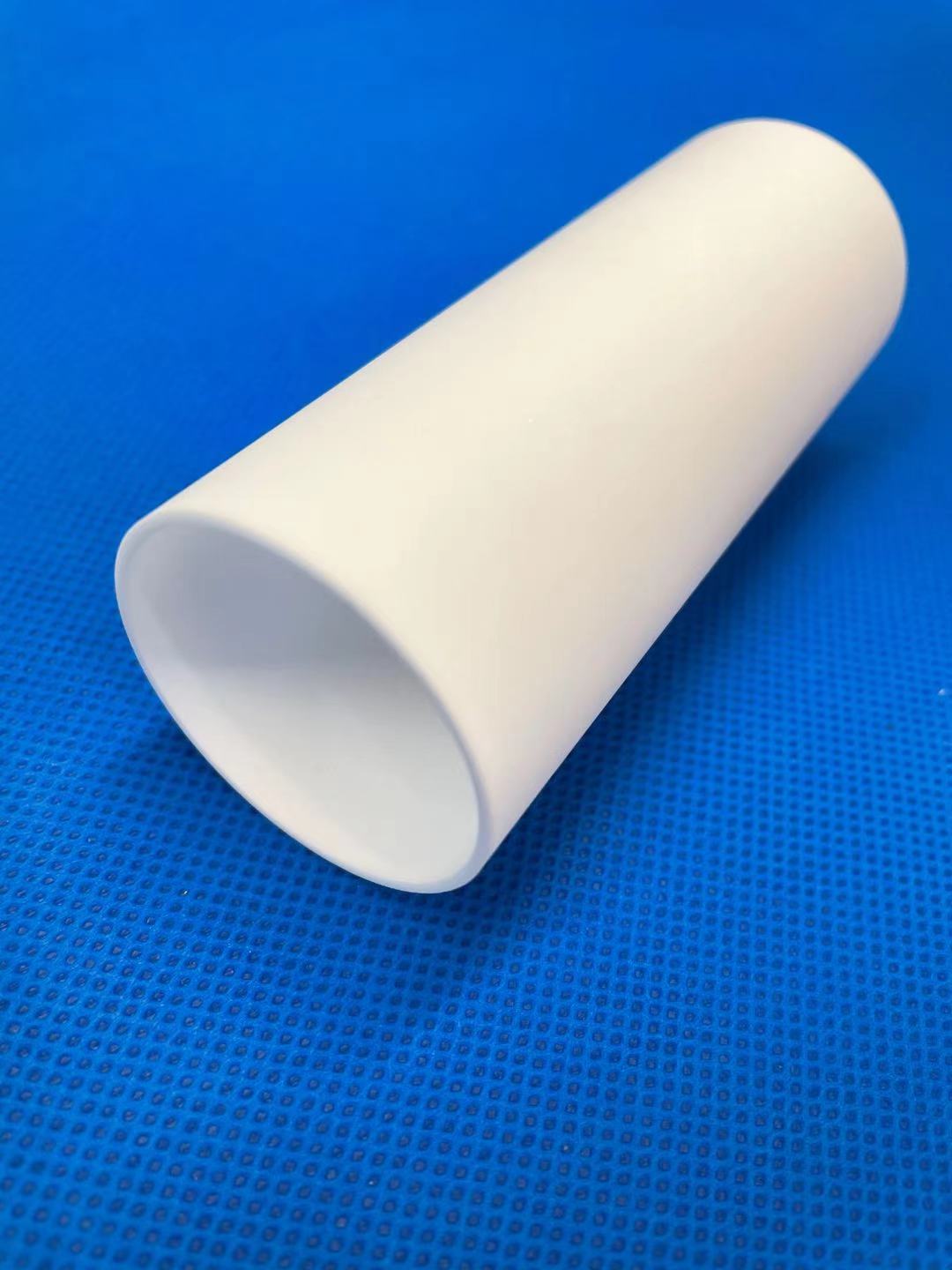

steatite ceramic is characterized by dielectric loss and low price, and can be used to manufacture high-frequency insulators, insulating tubes and coil bobbins.

EN

EN  CN

CN