The application fields of high-strength and high-insulation alumina ceramics

Alumina ceramicshave good conductivity, mechanical strength and high temperature resistance, and also have very good high insulation. Alumina ceramics is a very wear-resistant precision ceramic material, which is widely used in all walks of life.

The main molding methods of alumina ceramic products are: dry pressing, isostatic pressing, injection molding and casting. Different product shapes, sizes, complex shapes and precision products require different molding methods. High temperature sintered alumina ceramic products can only be machined using a diamond grinding process. Alumina ceramic material has extremely high hardness and wear resistance, strong corrosion resistance, high temperature resistance, corrosion resistance and biological inertness. In addition, alumina sintered at high temperature can be highly polished and is widely used in many fields.

So what are the application fields of alumina ceramics? Mingrui Ceramics will introduce you in detail.

Alumina Ceramic components

1. Mechanical aspects

The important advantage of alumina ceramics is that its flexural strength is quite high, and the degree of hot pressing is much higher than other similar materials.

In terms of Mohs hardness, it is invincible and has an exclusive advantage. In addition, it has a very good anti-wear ability. Therefore, it is often used to make knives, ceramic bearings, etc. Ceramic knives and industrial valves are the current aluminum oxide. Preferred choice for ceramic applications.

2. Electronics/electricity

Alumina ceramics also play a significant role in electronics and power. All kinds of ceramic substrates, ceramic membranes, transparent ceramics and insulating devices are inseparable from alumina ceramics.

In the major electronic business fields, transparent ceramics are an important direction for the research and application of current new technologies. Daidaidai not only has a high range of light transmittance, but also has a series of advantages such as high thermal conductivity, low electrical conductivity, and wear resistance. make it popular.

3. Chemical aspects

Alumina materials also have broad prospects in chemical industry. Whether it is a chemical filler ball or a corrosion-resistant coating, the inorganic polymer materials used must have high temperature resistance and good thermal stability.

Alumina ceramics will not be compressed under high strength and high pressure, can resist the erosion of organic solvents and chemical raw materials, can be used repeatedly, and meet the conditions of chemical work.

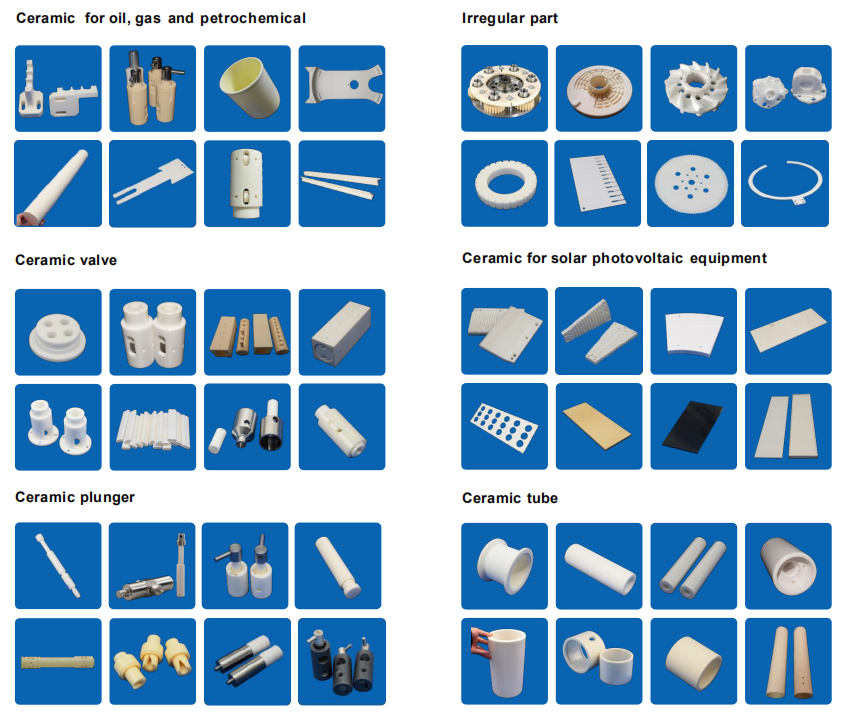

Alumina ceramic material is one of the most widely used important raw materials at present. Alumina ceramics with wear resistance, high resistance, high strength and high insulation properties are widely used in instrumentation, food and medical treatment, solar photovoltaic, mechanical appliances, laser semiconductors , petroleum machinery, automotive military, aerospace and other high-end fields. Common products include ceramic insulating rings, ceramic insulating sheets, ceramic substrates, ceramic arms, ceramic plungers, ceramic dispensing valves, etc. In addition, there have been important progress and significant breakthroughs in mechanical processing, medicine, aerospace, etc.

EN

EN  CN

CN