Products

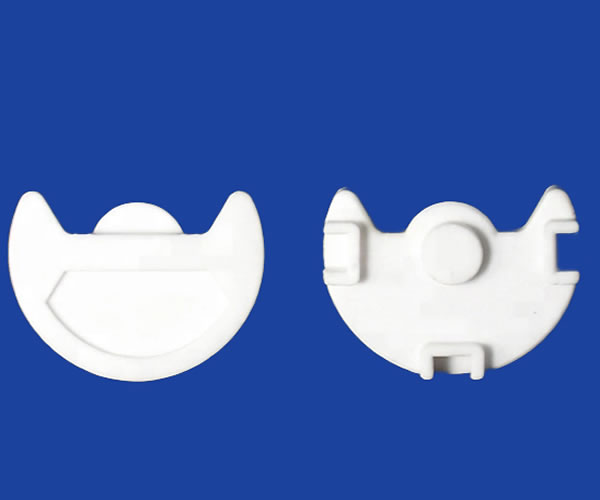

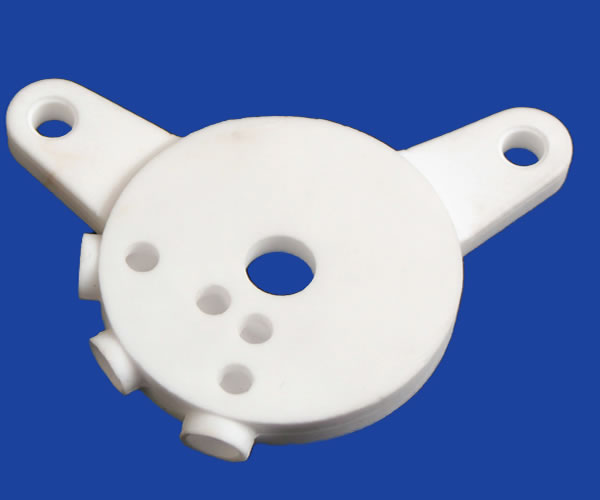

Ceramic valve plate disc custom cnc machined ceramic valve

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC

Sizes:Diameters: 0.5--150mm

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Ceramic valve plate Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Ceramic Valve Plate Custom Cnc Machined Wear-Resistant Ceramic Valve

We are a pro ceramic valve plate disc manufacturer, us sales and produce multi sizes and types of the ceramic plate type valve for pumps.high precision, factory price.

The ceramic valve we produced have have high hardness, high strength, wear resistance and good anti-corrosion performance, than any of the current corrosion-resistant alloy material valve core, can also be used in other strong corrosion and strong wear fluid medium switch and adjustment and other harsh operating conditions.

The type of ceramic valve we produce:

(1)closing door shape:the closing member moves along the center of the valve seat;Such as cut-off valve

(2)cock and ball:the closing member is a plunger or ball, rotating around its center line;Such as plug valve, ball valve

(3)gate shape:the closing member moves along the center of the vertical valve seat;Such as gate valves, gates, etc

(4)swing shape:the closing part rotates around the shaft outside the valve seat;Such as swing check valve

(5)butterfly:the disc of the closing part rotates around the axis in the seat;Such as butterfly valve, butterfly check valve, etc

(6)slide valve:the closing member slides in the direction perpendicular to the channel.Such as sliding

(7)other shapes:please contact us, we can custom by our customer requirments.

Features:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1....

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

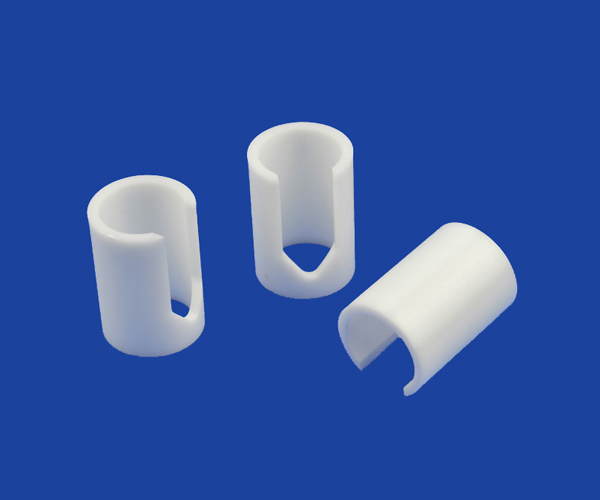

Other ceramic valve components:

ceramic sealing,ceramic seat, ceramic ball, ceramic washer, ceramic ring, ceramic bushing sleeve, ceramic rube, ceramic flanged, ceramic tube etc

For more sizes, types, application, price,delivery time etc details,please contact us soon , Mr admin [email protected]

Our ceramic engineer service , quicky feeback!!!

Materials parameter:

| Property | Alumina | Property | Zirconia |

| Bulk density(g/cm³) | 3.85-3.93 | The density (g/cm³) | 6.05 |

| Hardness(HRA≥) | 86 | Bibulous rate(%) | 0 |

| Bending strength(Mpa≥) | 300 | Thermal expansion coefficient(10-6 /k) | 10.5 |

| Maximum service temperature(℃) | 1500 | Young's modulus of elasticity(Gpa) | 210 |

| Linear expansion coefficient(×10-6/℃) | 7.15-7.67 | Poisson's ratio(/) | 0.3 |

| Dielectric constant(εr(20℃,1MHz)) | 9.21 | Hardness (MPa) | 1200 |

| Dielectric loss(tanδ×10-4,1MHz) | 2.5 | Bending strength (MPa) | 950 |

| Volume resistivity(Ω·cm(100℃)) | 9.2*1016 | The bending strength (MPa) | 210 |

| The compressive strength(Mpa≥) | 2500 | Compressive strength (MPa) | 2000 |

| Flexural strength(Mpa≥) | 200 | Fracture toughness(Mpa.m1/2) | 10 |

| Modulus of elasticity(Gpa) | 300 | Thermal conductivity (W/m.k) | 2 |

| Poisson's ratio | 0.2 | Specific resistivity(Ω.mm2/m) | >1015 |

| Thermal conductivity Coefficient(W/m·K(20℃)) | 20 | Maximum service temperature(℃) | 1350 |

| Dc breakdown strength | 43.7 | Acid and alkali corrosion resistance(/) | strength |

| Tensile seal strength(Mpa) | 104.4 |

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about ceramics parts,please contact our engineers in time >>>

EN

EN  CN

CN