Products

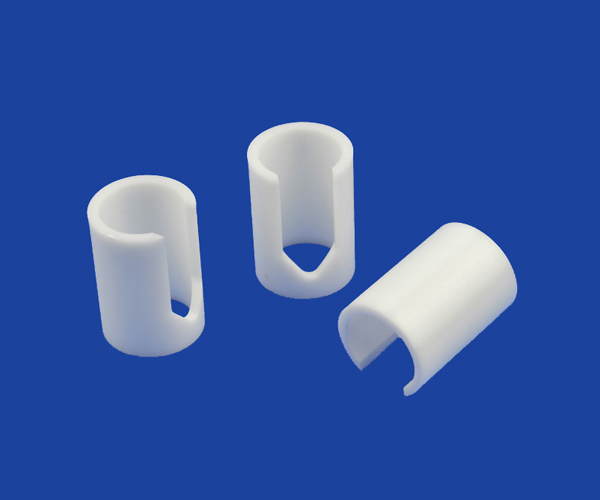

Ceramic Dispensing Valve

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Ceramic Dispensing Valve Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Ceramic Dispensing Valve

I. introduction to ceramic dispensing valve:

Applicable temperature: -40 ~ 1800 degrees

Applicable pressure: 1.0-4.0mpa

Working condition/medium:

all kinds of acid, alkali and salt gas, liquid, fixed and granular fiber media in power plant, steel mill, chemical industry, papermaking, energy mine and other systems.

Zirconia Ceramic Dispensing valve has good wear resistance, in the high hardness of granular media and soft corrosion of the dispensing valve with absolute selection advantages. Applicable media: Water treatment oil, boiler vapor, lime slurry, containing granular seawater transport, flue gas desulfurization, ash removal, slag discharge. Replacement materials by use, can be used for different temperatures, different use of the environment.

Fully lined hard sealing surface contact ceramic valve all contact with the media are structural ceramic materials, zirconia ceramics with high wear resistance, high temperature resistance, good heat insulation performance.

Materials parameter:

| Property | Alumina | Property | Zirconia |

| Bulk density(g/cm³) | 3.85-3.93 | The density (g/cm³) | 6.05 |

| Hardness(HRA≥) | 86 | Bibulous rate(%) | 0 |

| Bending strength(Mpa≥) | 300 | Thermal expansion coefficient(10-6 /k) | 10.5 |

| Maximum service temperature(℃) | 1500 | Young's modulus of elasticity(Gpa) | 210 |

| Linear expansion coefficient(×10-6/℃) | 7.15-7.67 | Poisson's ratio(/) | 0.3 |

| Dielectric constant(εr(20℃,1MHz)) | 9.21 | Hardness (MPa) | 1200 |

| Dielectric loss(tanδ×10-4,1MHz) | 2.5 | Bending strength (MPa) | 950 |

| Volume resistivity(Ω·cm(100℃)) | 9.2*1016 | The bending strength (MPa) | 210 |

| The compressive strength(Mpa≥) | 2500 | Compressive strength (MPa) | 2000 |

| Flexural strength(Mpa≥) | 200 | Fracture toughness(Mpa.m1/2) | 10 |

| Modulus of elasticity(Gpa) | 300 | Thermal conductivity (W/m.k) | 2 |

| Poisson's ratio | 0.2 | Specific resistivity(Ω.mm2/m) | >1015 |

| Thermal conductivity Coefficient(W/m·K(20℃)) | 20 | Maximum service temperature(℃) | 1350 |

| Dc breakdown strength | 43.7 | Acid and alkali corrosion resistance(/) | strength |

| Tensile seal strength(Mpa) | 104.4 |

EN

EN  CN

CN