Products

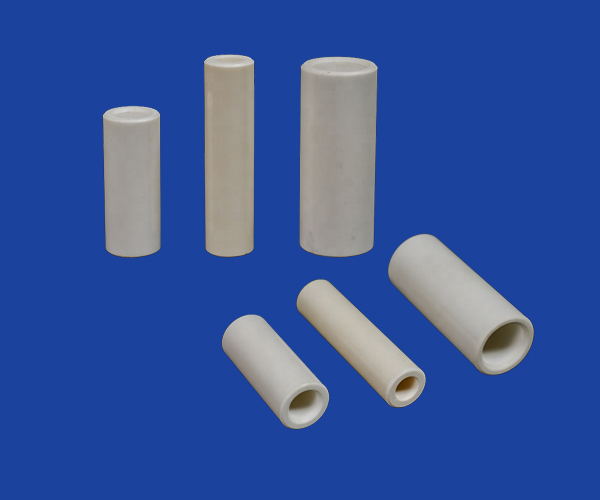

Ceramic tube parts for fitting adapter sockets

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Mini-OD: 0.02mm;Max-length: 500mm

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

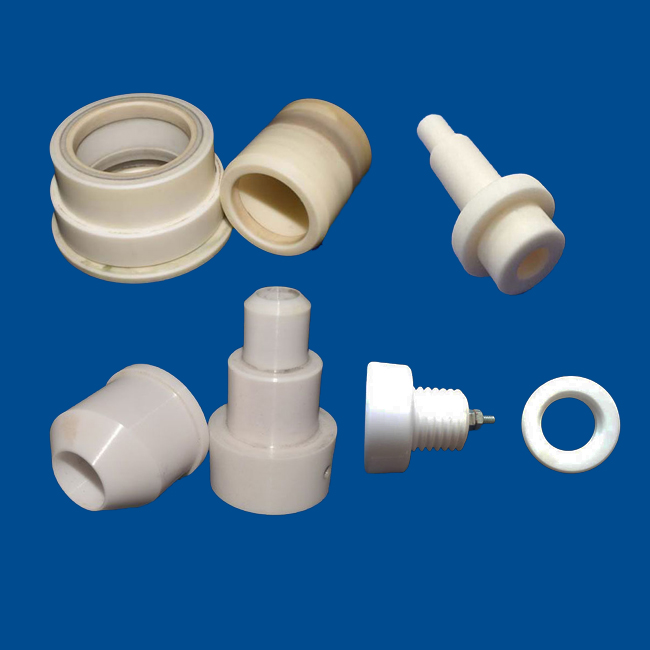

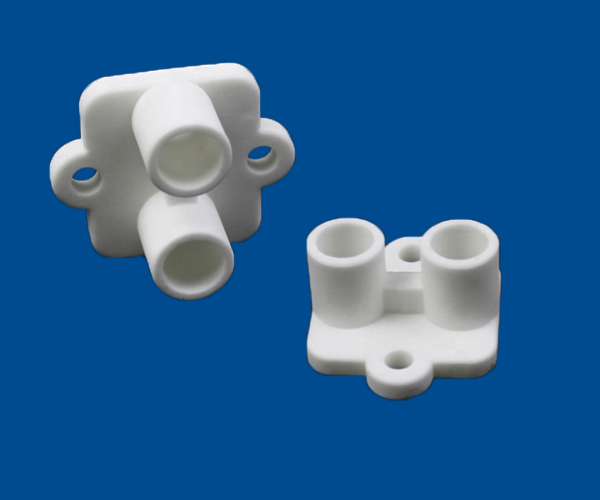

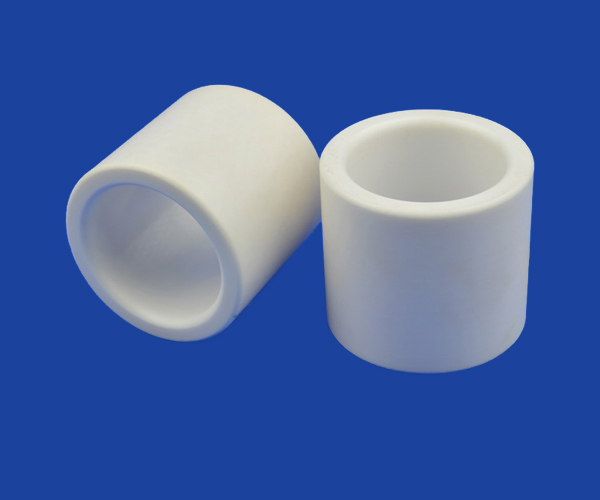

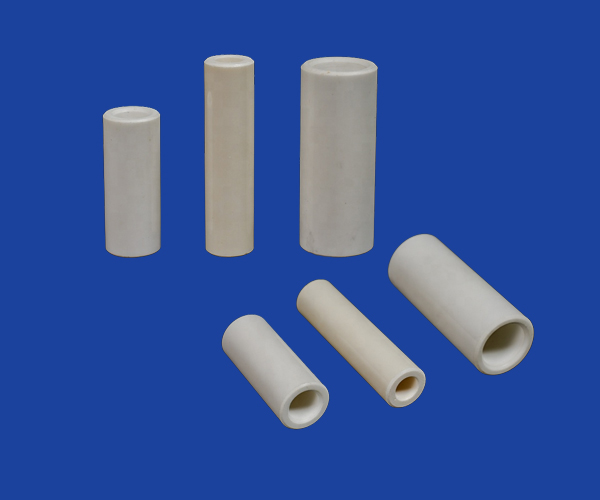

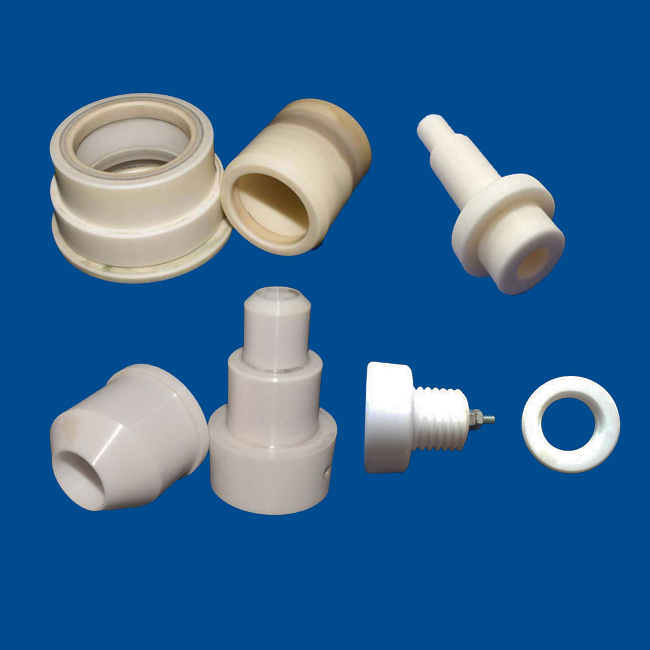

Ceramic Tube Fitting Adapter Best Ceramic Tube Sockets Alumina Zirconia Silicon Ceramic Tube Parts

Ceramic tube fitting as a parts of the tube or pipe have a best performance for industry. which made of the advance ceramic raws: 95%-99.99% alumina ceramic(Al2O3); zirconia ceramics; silicon carbide ceramics; silicon nitride ceramics..etc

Ceramic tube fitting, ceramic tube sockets with insulation resistance, voltage resistance, high strength, good thermal conductivity, dielectric loss, stable electrical performance characteristics. Used in electronic ceramic substrates, ceramic electrical insulation, vacuum devices, devices porcelain, spark plugs and other products.

Ceramic tube fitting socket features:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength, Wear Resistance Up To Mohz 9.0 Levels...

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

6. Long Service Life...Other excellent property

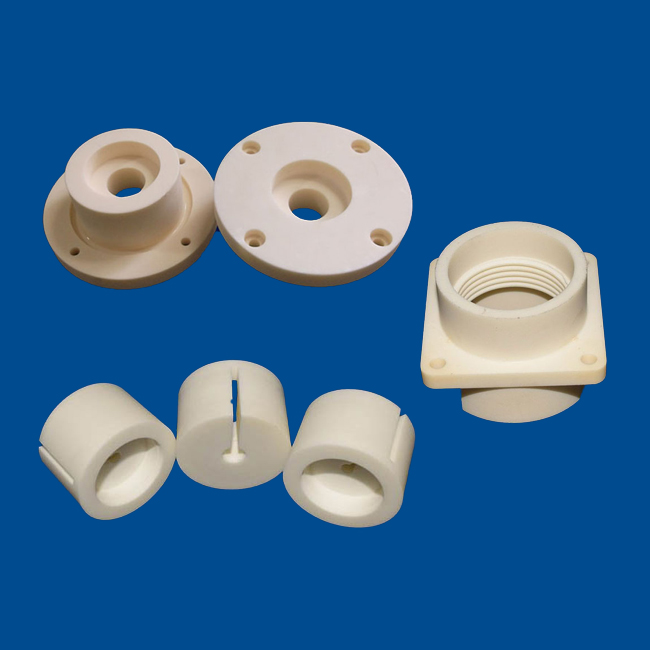

Ceramic fitting socket application:

Furnace construction (heat conductor supports, pipes, burner nozzles)

Hot air generators (multi-hole pipes, honeycombs)

Heating element production (helical coil cartridges, cast-iron radiators)

Foundry technology such as cast steel (immersion-type sensors, moulded parts for foundries, casting filters)

Welding technology (Welding ceramics in the form of welding tubes, welding bars, welding chips)

and many others industry and machines

Some ceramic tube fitting show like below:

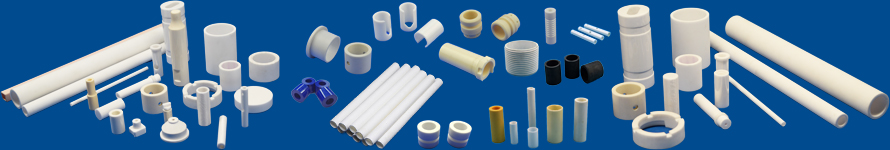

Type of ceramic tubes us manufacturer (including but not only belows)

| Thermocouple protection tube Insulated tube Inner core | Furnace tube Heating tube Radiant tubes | Pump body tube Inner liner tube Round tube | Bushing tube Roller tube Single / mutli holes tube | ||||

| Dimension : | |

| Inside Diameter as small as 0.3 mm | Longth as long as 500mm, as short as 0.5mm |

| Inside Diameter tolerance as 0.002mm | Outside Diameter tolerance as fine as 0.001mm |

| Minimum thickness of tube wall:0.2mm | The length and special sizes can be customized |

Other ceramic tubes products

ceramic tube insulators ceramic tube socket ceramic tube core ceramic tube cylinders

ceramic tube heater ceramic tubing plunger ceramic tube ferrule others

User industries

automotive, aviation, space travel

electrical and thermal insulation

electronics and sensors

energy technology, power generation

environmental technology

fluid technology

friction-reduction, wear- and corrosion -protection

high temperature applications

laboratory technology

laser technology

mechanical and chemical process engineering

metal industry

optics

semiconductor processing equipment

surface treatment

vacuum technology

Ceramic materials(include but not limited belows)

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

| Al2O3 | ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN | |

| Physical properties | ||||||||

| Density (g/cm³) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >1014 | 1013-1014 | >1010 | - | 102-106 | >107 | 1012- 1015 | >1014 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL.

Our Custom Capabilities:1.High Purity Martoxid Powder

2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience

3.35000 ㎡workshop, annual output could reach hundred million pieces.

4.All crafts are inspected strictly based on drawings,checked each month.

5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Lead time:within 20 working days after comfirmed order. the samples within 3 days

| Technical reference of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about ceramics parts,please contact our engineers in time>>>

EN

EN  CN

CN