Products

Ceramic insert tube custom multi alumina zirconia ceramics pipes

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

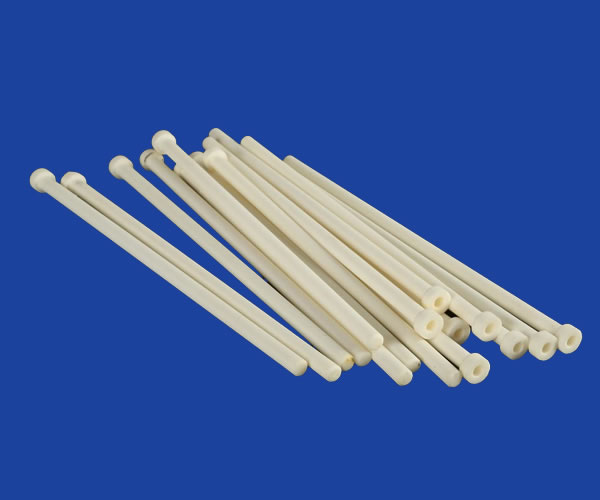

Sizes:ID:0.5--145mm;OD:1--150mm;Length:3--800mm

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Ceramic insert tube custom multi alumina zirconia ceramic pipes

Ceramic insert tubecan be used for many parts in defferant industries. due to the ceramic insert tube have a excellent ceramic ability than metal inserts.

Ceramic insert tube was produced by our factory include alumina ceramic insert tube, zirconia ceramic tubes and other ceramic insert with other raws.

The feature of the ceramic insert tubes:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength, Wear Resistance Up To Mohz 9.0 ; HRA 80-90...

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, MAX 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

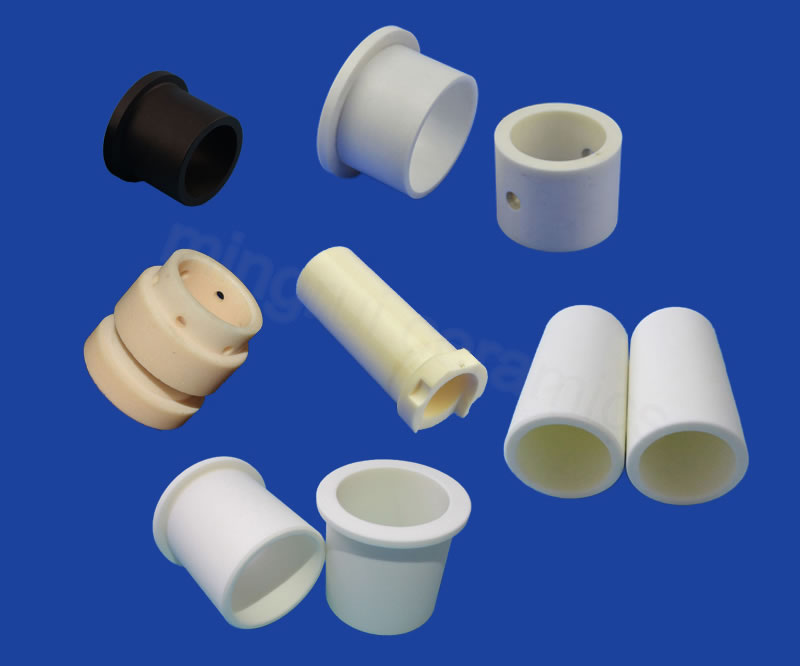

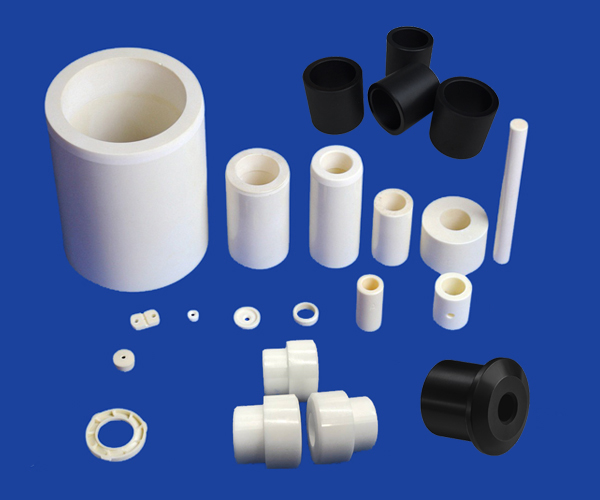

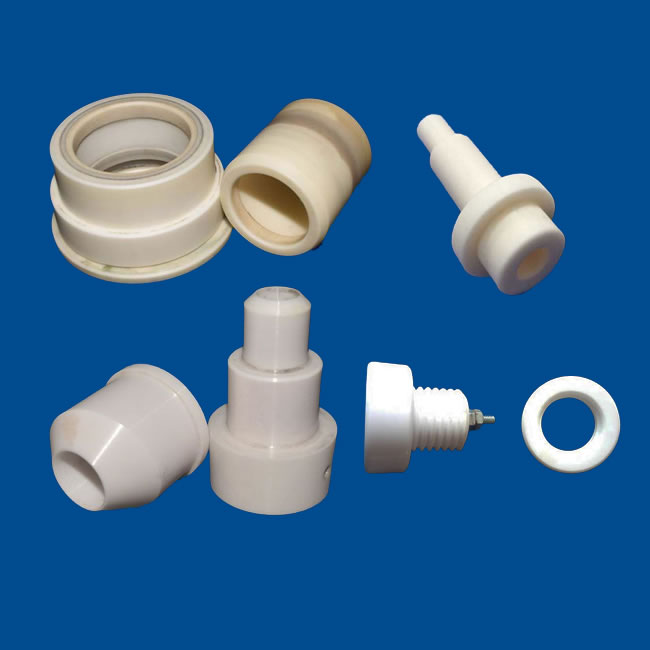

The shapes of our ceramic insert tubes:

We manufacture ceramic insert tube shapes in both popular and custom types.Customization type:

Tubular: Short, long

Flanged: one flange, two flanges

Thread: all threads, one thread, internal thread

The pipe punching

semicircle

The specific shape and parameters of the ceramic insert tube can be manufactured according to the requirements of our customers.

User industries

automotive, aviation, space travel

electrical and thermal insulation

electronics and sensors

energy technology, power generation

environmental technology

fluid technology

friction-reduction, wear- and corrosion -protection

high temperature applications

laboratory technology

laser technology

mechanical and chemical process engineering

metal industry

optics

semiconductor processing equipment

surface treatment

vacuum technology

Ceramic materials

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

| Precision of manufacture ceramics insert tube | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

| Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface | |

EN

EN  CN

CN