Products

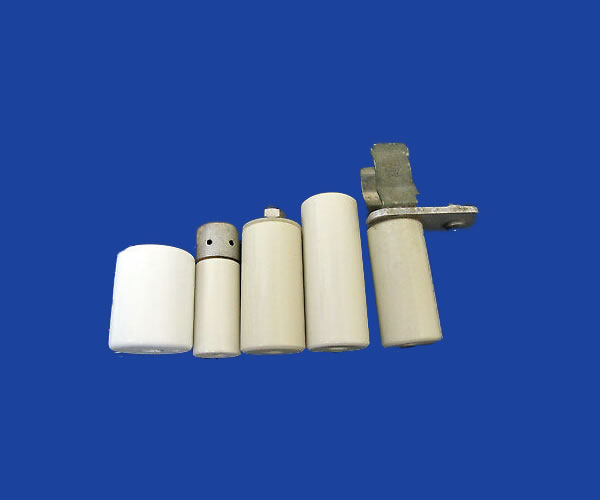

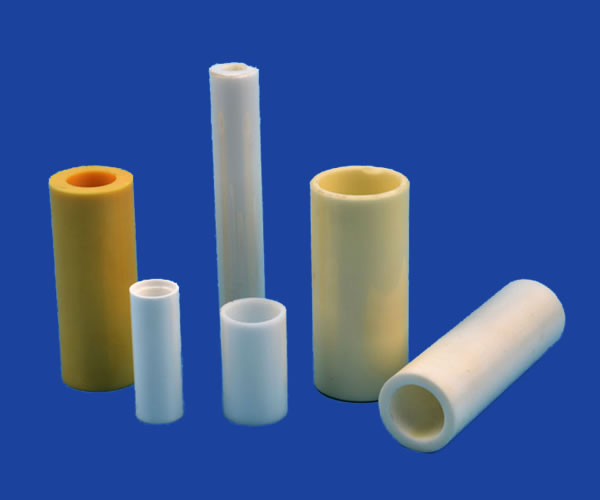

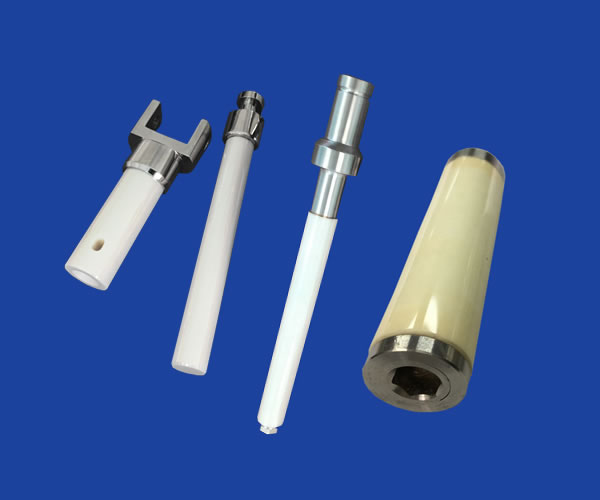

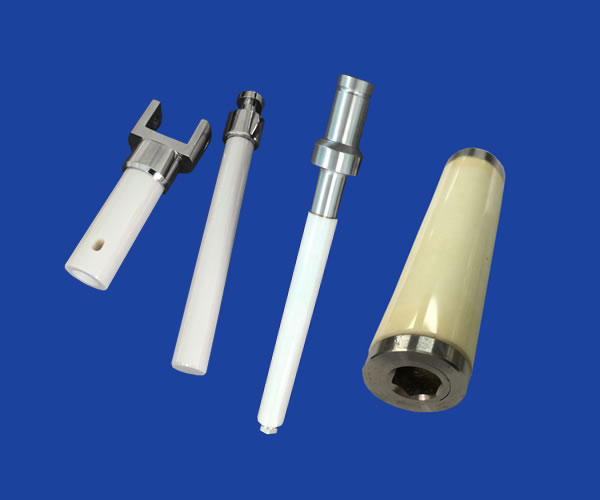

Alumina ceramic plunger 99% to 99.99% Al2O3 purity alumina plungers

Materials:Alumina ceramina(Al2O3)95%;96%;97%;98%;99%;99.5%:99.7%;99.9%

Sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:

Ceramic plates sheet substrate disc series

Alumina ceramic plunger 99% to 99.99% Al2O3 purity alumina plungers

We are a pro alumina ceramic plunger factory, we produced multi alumina plunger which alumina ceramic Al2O3 purity like Alumina ceramina(Al2O3)95%;96%;97%;98%;99%;99.5%:99.7%;99.99% etc according to customer requirements.

Special alumina ceramic plunger properties

High purity of 99,7%

High mechanical strength and wear resistance

Excellent thermal resistance

Outstanding insulation characteristics

Extreme dielectric strength

Exceptional tribological properties

Can be processed with conventional abrasive tools

Low dissipation factor

High chemical resistance

Good metallizability

Very hard material structure

Notes:

For more details of the ceramic plungers or the best price , please send your requirements to our ceramic engineers(official E-mail: [email protected]). thanks

The mechanical characteristics of advanced Al2O3 ceramic materials are also remarkable. Hence, aluminum oxide materials are often used when components must withstand high mechanical load as Al2O3 offers an excellent wear resistance. So due to its superior tribological, much longer lifetimes of parts and workpieces can be achieved with Al2O3. Furthermore, the chemical strength of alumina is considerable. It can resist most acids and alkalis even at increased temperatures.alumina plunger better performance than metals in high temperature,soomthness, corrision applications.

Specifications of 99,7% Al2O3 alumina plungerRaw Density

3,75 - 3,94 g/cm³

Purity

99,7% Al2O3 (Alumina /Aluminium oxide)

Coefficient of Expansion

78 x 10-7 / °C (20 - 700°C)

86 x 10-7 / °C (20 - 1000°C)

Thermal

Max. operating temperature under mechanical load: approx. 1700°C

Good thermal shock resistance Specific heat capacity: 990 J kg-1 K-1 (20 - 100°C)

Mechanical

Modulus of elasticity: 300-380 GPa

Mohs hardness: 9

Modulus of rupture: 300 Gpa (20°, 3-Point)

Electrical

Electric strength: 17 kV/mm (IEC 672-2)

Specific DC-resistance: 1014 Ω cm (20°C)

Other specifications

Water absorption capacity: ≤ 0,2%

Leak rate: 10-10 hPa dm3 s-1 (20°C)

| Technical reference of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

Customization & Machining Service:

As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL.

Our Custom Capabilities:

1.High Purity Martoxid Powder

2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience

3.35000 ㎡workshop, annual output could reach hundred million pieces.

4.All crafts are inspected strictly based on drawings,checked each month.

5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Lead time:within 20 working days after comfirmed order. the samples within 3 days

EN

EN  CN

CN