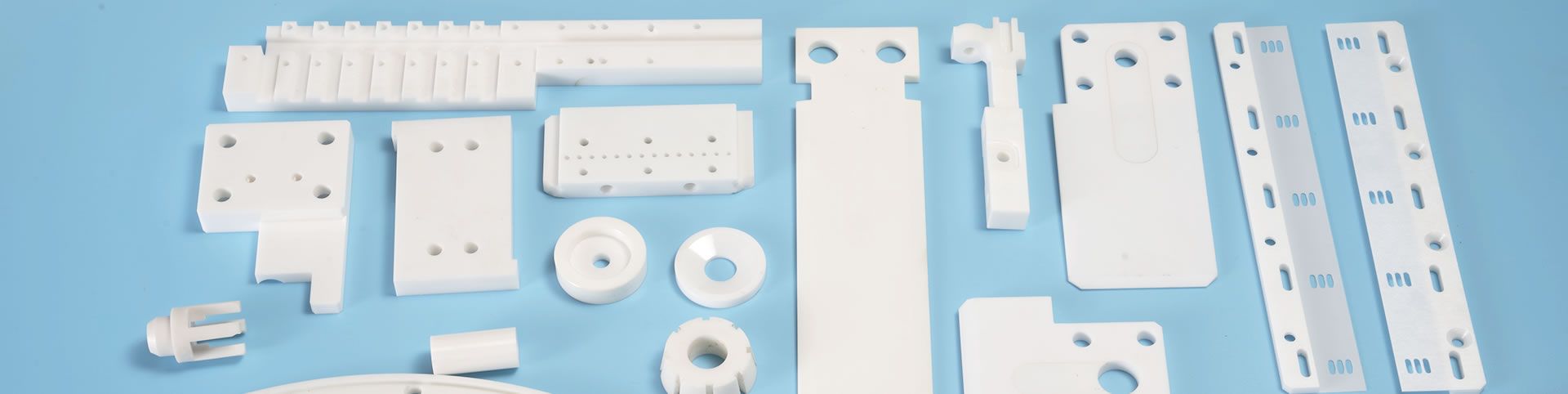

Products

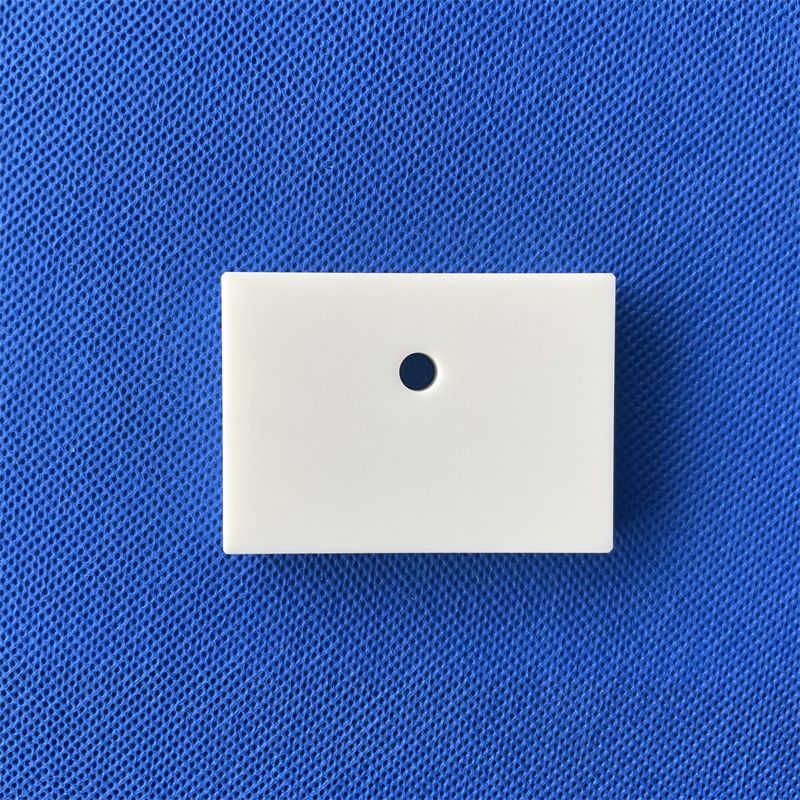

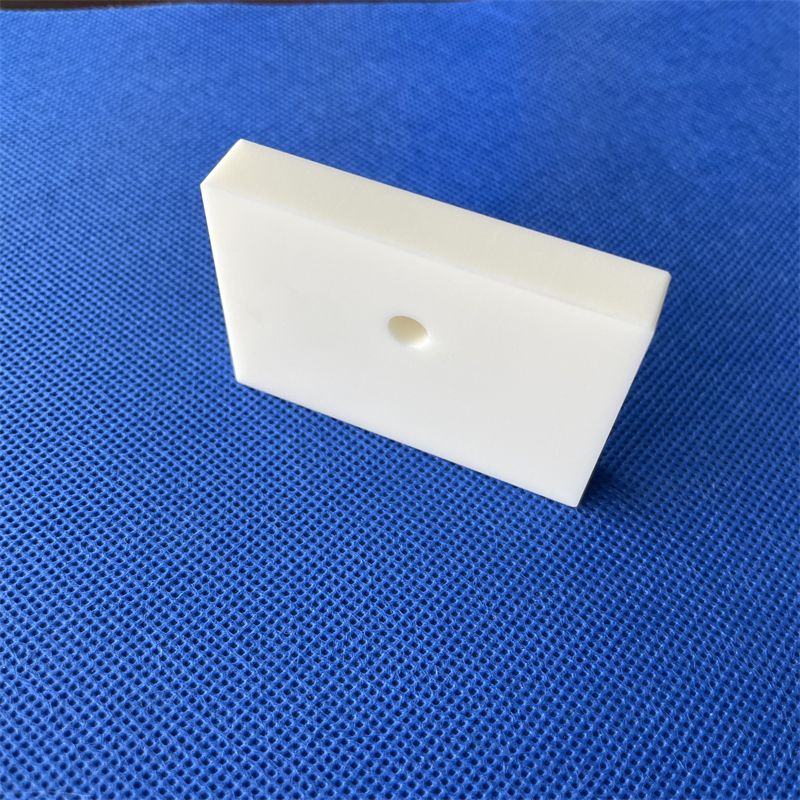

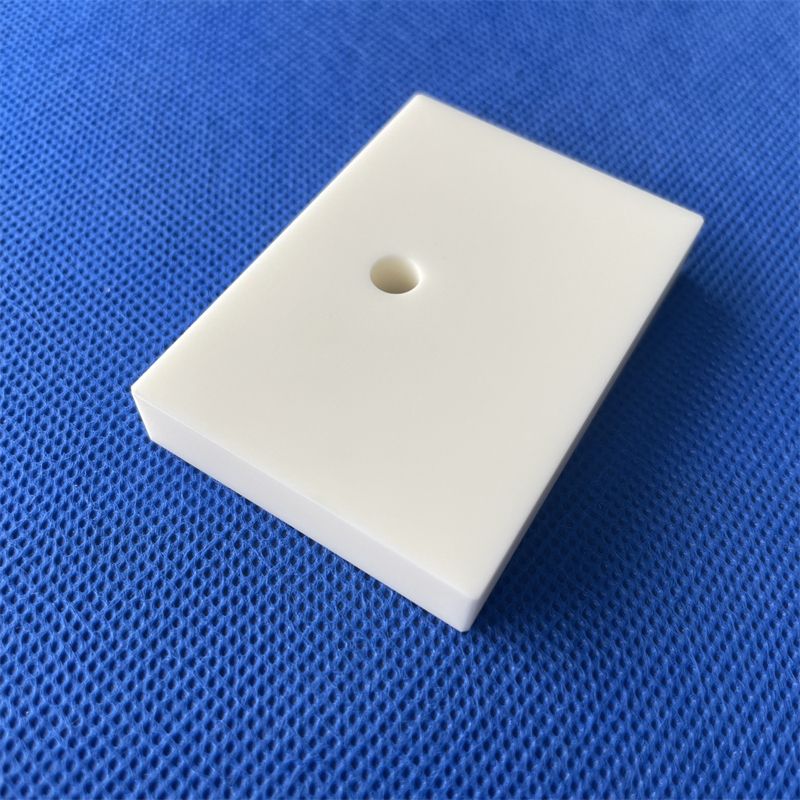

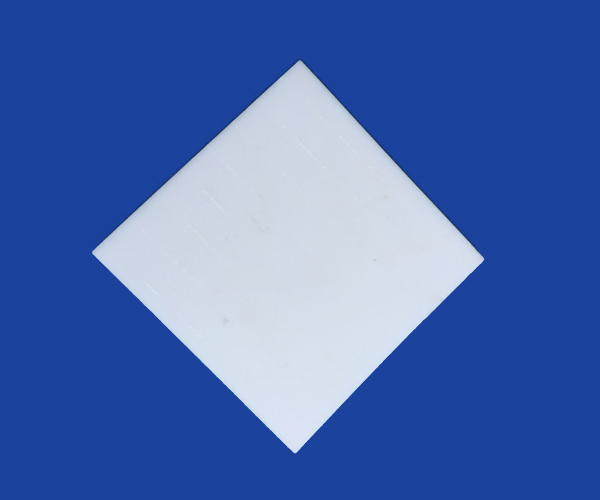

Alumina ceramic plate High strength High hardness alumina ceramic support plate

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4/SiC

Sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

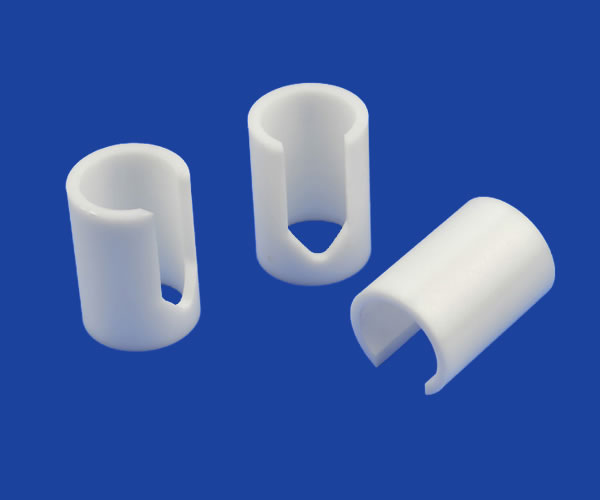

Customized:Ceramic valves and valve components Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

Alumina ceramic support plate is a flat or specific shape structural part made of high-purity alumina (Al₂O₃) ceramic material, mainly used to support workpieces, components or other equipment in harsh environments with high temperature, corrosion, wear or excellent electrical insulation.

The following is the key characteristics and application information about alumina ceramic support plates:

Core characteristics

1. Extremely high temperature resistance:

The melting point of alumina ceramics is very high (about 2050°C).

The support plate can be used in air at long-term operating temperatures of up to 1600°C - 1750°C** (depending on the purity of alumina, such as 99% Al₂O₃ or 95% Al₂O₃). It can withstand higher temperatures in the short term.

It is much better than metals and most other non-oxide ceramics (silicon nitride and silicon carbide are easily oxidized at high temperatures in air).

2. Excellent mechanical strength and hardness:

It has high compressive strength and good flexural strength (typical flexural strength is 300-400 MPa or even higher, depending on purity and process), and can withstand heavy loads.

The extremely high hardness (Mohs hardness 9, second only to diamond) makes it have excellent wear resistance and can resist friction and scratches from materials or workpieces.

3. Excellent chemical stability:

It is extremely resistant to most acids, alkalis, molten metals and salts (except hydrofluoric acid and hot alkaline solutions).

It is not easy to react with the furnace atmosphere or processed materials at high temperatures, avoiding contamination.

4. Excellent electrical insulation:

Even at high temperatures, it has a high resistivity and is an ideal electrical insulation support component, especially suitable for sintering or heat treatment of electronic components.

5. Low thermal expansion coefficient:

The thermal expansion coefficient is relatively low, and it has good dimensional stability and thermal shock resistance when the temperature changes sharply (although not as good as some other special ceramics such as silicon nitride and zirconium oxide, but in alumina ceramics, it can achieve a better level through formulation and design optimization).

6. Good thermal conductivity:

The thermal conductivity is worse than many other ceramic materials, which helps to achieve a more uniform temperature distribution during heat treatment (although not as good as aluminum nitride or silicon carbide).

7. High rigidity and dimensional stability:

It has minimal deformation under high temperature load and can maintain precise geometry and flatness.

Main application areas

1. Heat treatment industry:

Sintering furnace: supports electronic components (MLCC, ceramic substrates, magnetic materials, powder metallurgy parts, etc.) for high-temperature sintering. It is the most core and most widely used application.

Push plate furnace, roller kiln: as kiln tools (push plate, support plate, support plate) to carry products through the high-temperature zone.

Annealing furnace, brazing furnace: support metal parts for heat treatment.

Experimental electric furnace: used to place crucibles, samples, etc. in the laboratory.

2. Electronic industry:

Semiconductor manufacturing: used as a support plate or partition for wafer boats in diffusion, CVD, PVD and other processes.

Electronic component firing: supports PCB boards, electronic pastes, ceramic substrates, etc. for curing or co-firing in high-temperature furnaces.

3. Photovoltaic industry:

Solar cell manufacturing: used as a carrier plate or transmission plate for silicon wafers in PECVD, sintering and other processes.

4. Glass and ceramic industry:

Support and transmission components in the process of glass melting, forming and annealing.

Kiln tools for firing ceramic embryos.

5. Metallurgy and powder metallurgy:

Crucible supports and casting launder plates for high-temperature molten metals.

Sintering plates for powder metallurgy parts.

6. Other industries:

Chemical industry: Support grids for corrosion-resistant reactors.

Laser cutting: Support platform for high-precision workpieces.

Friction and wear testing machine: As wear-resistant table.

Manufacturing process

Raw materials: Use high-purity (90%-99.9% and above) alumina powder.

Molding: Mainly adopt dry pressing or isostatic pressing.

Dry pressing: High efficiency, low cost, suitable for plates with relatively simple shapes and low dimensional accuracy requirements.

Isostatic pressing: The density uniformity of the green body is excellent, and large-sized, complex-shaped, high-precision, high-performance support plates can be manufactured, with higher strength and better thermal shock resistance, but the cost is also higher.

Sintering: It is carried out in a high-temperature kiln (usually above 1600°C) to densify the powder particles and form a solid ceramic body.

Processing: After sintering, precision processing (such as surface grinding, grinding, polishing) is usually required to achieve the required dimensional accuracy, parallelism and flatness. Drilling, grooving, etc. may also be required.

Advantages Summary

Extremely high temperature resistance: Stable operation at temperatures that metals cannot withstand.

Ultra-long service life: Excellent wear resistance, corrosion resistance, and high-temperature creep resistance make its service life far longer than that of metal kiln furniture, reducing downtime and replacement time and reducing overall costs.

High cleanliness: Extremely low gas release and almost no pollution, ensuring the purity of the processed products (especially in the electronics and photovoltaic industries).

Excellent stability: No deformation at high temperatures and high dimensional accuracy.

Excellent insulation: safe and reliable.

Selection considerations

Alumina purity: Plates with a purity of more than 99% have the highest high-temperature performance, strength and corrosion resistance, but are also the most expensive. 95% purity is a common choice with a high cost-effectiveness.

Size and thickness: Determined by load and furnace space.

Flatness and parallelism: Critical for precision applications (such as semiconductors, electronics).

Surface finish: Whether grinding or polishing is required to reduce sticking or contamination.

Special design: Whether holes, grooves, edge chamfers, etc. are required.

Thermal shock resistance requirements: For applications with drastic temperature changes, plates made with specific formulas or processes (such as isostatic pressing) need to be selected.

In summary, alumina ceramic support plates are indispensable key components in harsh industrial environments with high temperatures, corrosion, wear and insulation. With their unparalleled comprehensive performance (especially high-temperature stability), they play a core role in electronics, photovoltaics, heat treatment, metallurgy and other fields. When selecting, it is necessary to determine the appropriate material specifications and processing accuracy based on specific application conditions and requirements.

Delivery:

Arrange shipment of stock products within 2 days

Custom OEM will be shipped within 15 days after determining the parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the ceramic wear plates, please contact us or

email:[email protected]

Availible Ceramic materials of wear ceramic plate(include but not limited belows)

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)...

Customization & Machining Service:

As a wear ceramic plate manufacturer,us offer a wide of the wear ceramic plate specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL.

Our Custom Capabilities:

1.High Purity Martoxid Powder

2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience

3.35000 ㎡workshop, annual output could reach hundred million pieces.

4.All crafts are inspected strictly based on drawings,checked each month.

5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

| Technical reference of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

For more information about wear ceramic plates,please contact our engineers in time >>>

EN

EN  CN

CN