How to distinguish between zirconia ceramics and alumina ceramics?

As new ceramic materials, zirconia ceramics and alumina ceramics have many excellent properties and are widely used. What is the difference between zirconia ceramics and alumina ceramics? What's the difference? How should we judge whether it is zirconia ceramics or alumina ceramics? The following Mingrui Ceramics will tell you how to distinguish these two types of ceramics.

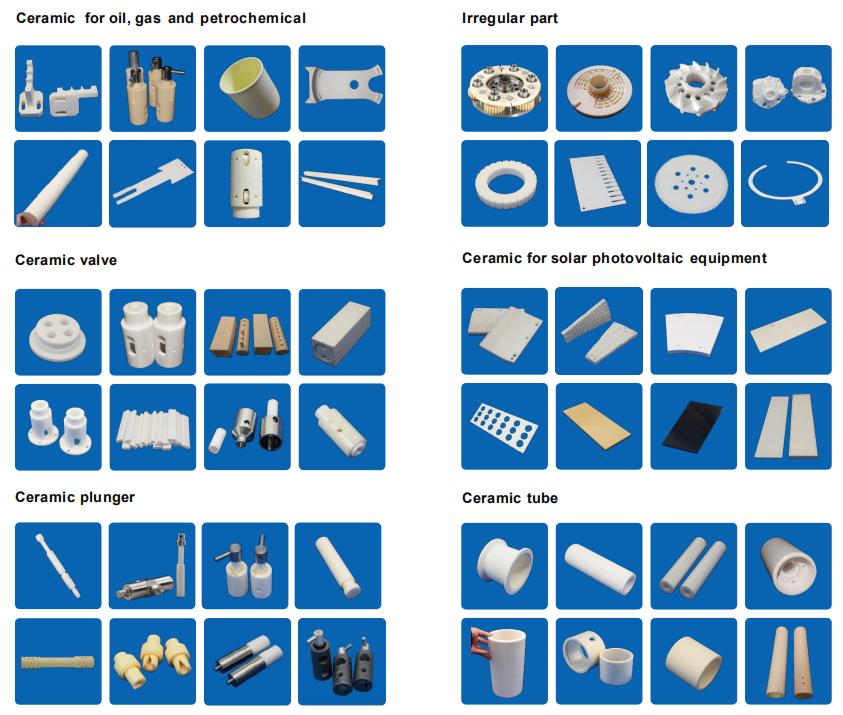

zirconia and alumina ceramic structural parts

Comparison of the advantages of zirconia ceramics and alumina ceramics: Comparison of ceramic toughness: The toughness of zirconia ceramics is 4 times that of alumina ceramics. At the same time, zirconia can be freely dropped from a height of one meter, but there will be some gaps in the alumina. Lose.

Density comparison: The density of zirconia ceramics is twice that of alumina ceramics. In contrast, zirconia has better compressive performance.

Comparison of friction coefficient: friction and hard wear of zirconia ceramics. Which material can be wear-resistant depends on the actual use.

Density comparison: The density of the zirconia ceramic structure is higher than that of the alumina ceramic. The density of the alumina ceramic is 3.5. The density of the zirconia ceramic structure is 6. The texture is more delicate, and the surface finish is higher after grinding. , Up to ▽9 or more, is mirror-like, extremely smooth, and has a smaller friction coefficient.

Surface finish comparison: The zirconia ceramic structure has a higher surface finish, which is mirror-like, extremely smooth, and has less friction with the net, which can further increase the service life of the net, greatly reduce the net consumption, and reduce the current of the paper net. Reduce electricity consumption.

In addition, the toughness of the zirconia ceramic structure is excellent, which overcomes the inherent brittleness of the ceramic itself, has higher wear resistance, greatly prolongs the service life of the product, and significantly improves the quality.

EN

EN  CN

CN