Advantages of Advanced Ceramic Nozzles

Ceramic nozzles(also called advanced ceramic nozzles or special ceramic nozzles) are widely used in PCB equipment and etching machines. The specifications of ceramic nozzles are various. The media contained in the equipment include water, etching liquid, cleaning liquid and some corrosive industrial solvents. Overall Speaking of precision ceramic nozzles, which enable quick and easy replacement without the need to replace the nozzle body, what are the advantages of advanced ceramic nozzles? Why do many acids and alkalis need to use it to spray? Mingrui Ceramics will explain.

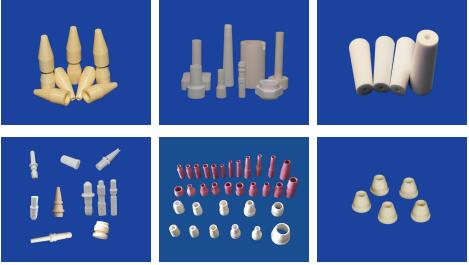

alumina zirconia ceramic nozzles

What are the advantages of ceramic nozzles?

1. Prevent leakage

The products produced by the sintering manufacturers of precision ceramic parts can be self-tilting, which can make the rotation installation faster, and also have a mechanical stop function, so the ceramic nozzle can achieve fast spray calibration, and the ceramic nozzle can be equipped with a sealing ring to prevent accidental leakage. Due to the strong airtightness of the ceramic nozzle itself, there is little overflow during work.

2, super wear resistance

The market of precision ceramic parts has been improving all the way. In view of the special industrial materials and structure of the ceramic nozzle, it can have a super wear-resistant function. Its hardness and toughness are both high and the friction coefficient is low. Most cutting tools need to use ceramic nozzles, and in recent years, some precision ceramic bearings and parts in the automotive industry also favor ceramic nozzles.

3. Super corrosion resistance

The important feature of the ceramic nozzle is its super corrosion resistance. It can be seen from its use medium that its high life is directly related to corrosion resistance, because most product materials cannot be directly contacted with etching solution or cleaning. However, the ceramic nozzle can perfectly control various corrosive liquids, and its super anti-corrosion has also achieved its long service life.

Judging from the physical and chemical properties of the material of the ceramic nozzle, it is relatively dense but has an extremely low friction coefficient. The high toughness overcomes its inherent brittleness, so precision ceramic nozzles have become irreplaceable products for many industries.

EN

EN  CN

CN