Products

Ceramic gasket with high temperature insulatoring

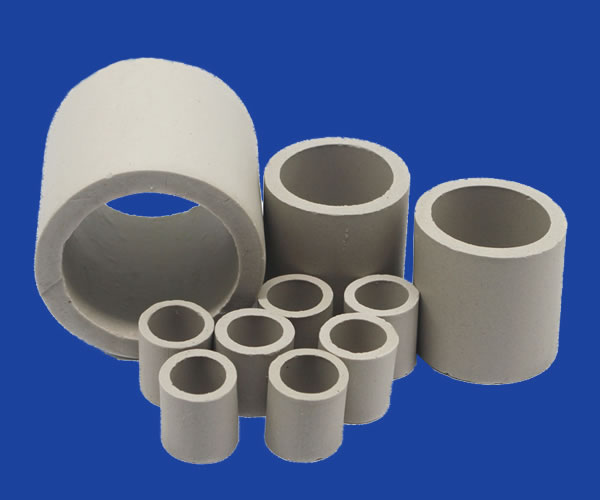

Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

Sizes:Custom according to the drawings

Delivery times:2 -25 days(depends on the quantity)

Precision:Ra 0.1um tolerance: 0.001mm... etc

Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

Customized:Can be custom for special sizes and shapes

Ceramic plates sheet substrate disc series

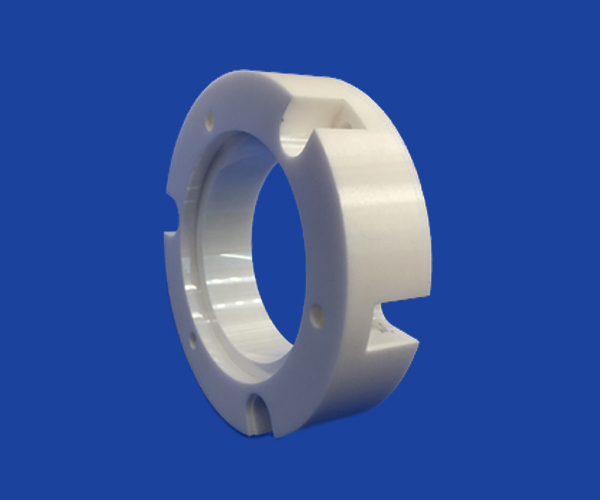

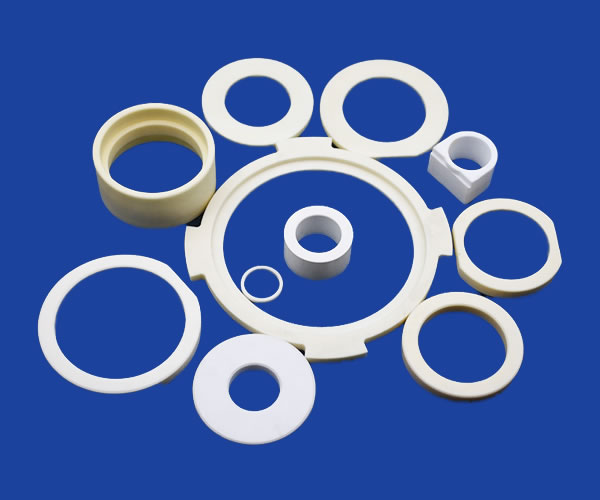

High temperature insulating ceramic gasket

High temperature insulating ceramic gasket is one of the most widely used ceramic gaskets in the industrial field. It is made of various advanced ceramic materials in different proportions, such as zirconia, alumina and silicon nitride.The chemical corrosion of ceramic gaskets can be solved by changing the material combination of ceramic gaskets.In order to strengthen the main body and accurately locate the metal internal strengthening ring and external positioning ring, the use of internal and external ring to control its maximum compactness plays a strengthening role and avoid the basic body of the loose ring, because the existence of external ring makes gasket installation more convenient.

Performance characteristics:

Can withstand high temperature, high pressure and adapt to ultra-low temperature or vacuum conditions of use, gasket contact flange sealing surface precision requirements are not high, easy to disassemble。

Equipment used:

Sealing at flange joints of pipes, valves, pressure vessels, condensers, heat exchangers, towers, manholes and hand holes in petroleum, chemical, metallurgy, electric power, ship, machinery and other industries.

Ceramic gaskets are divided into four forms: basic type, used for tenon flange gaskets;Sealing gasket with inner ring for embedding concave and convex flange;Gasket with outer ring for smooth plain welding flange;Sealing gaskets with inner and outer rings for smooth butt welding flanges.

High temperature insulating ceramic gasket is the most widely applied and cost effective technical ceramic material. It offers a combination of superior mechanical strength properties, wear resistance and corrosion resistance. The maximum working temperature is up to 1750 °C with relatively high thermal conductivity. It is also an electrically insulating material with a high electrical resistivity. The good corrosion resistance makes it insoluble in water and slightly soluble in strong acid and alkaline solution.

Ceramic washer material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

Shape :Round , square etc

Available color :black , white , yellowish etc

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm³ | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Thermal shock resistance | △T(℃) | 180-220 | 280-350 | 230-260 | / |

| Tensile strength | MPa | 248 | 250 | / | / |

Precision of manufacture

Dimensional accuracy: Up to 0.001mm

Smoothness: Highest possible mirror

Concentricity: Up to 0.003mm

Parallelism: Up to 0.002mm

The inner hole tolerance: The minimum 0.005mm

Straight flute: The narrowest 0.1x100mm

The thickness of the size: Minimum to 0.02mm

The screw thread: Minimum internal thread M2

Cylindricity: Up to 0.004mm

The linear tolerance: Up to 0.001mm

The smallest aperture: The minimum 0.07mm

Precision process: CNC maching,grinding,lapping

Surface finish: Glazed,polishing or metallized

Visual quality:

1. No cracks, no dark dots, no contamination and sharp edges;

2. Evenly distributed glaze with very smooth surface

Company Introduction

Mingrui ceramic manufacture and provides alumina ceramic components for a wide range of application like Mechanical Equipment, Electronic & Electrical, Oil Drilling, Medical, Chemical Industry etc. According to actual application and customer's requirement, the purities vary from 95%-99.7% and the forming methods will be different. The forming methods applied in our plant include dry pressing, isostatic pressing, injection moulding, extrusion moulding. With experienced engineers and talented workers, we are confident to offer high quality, high precision, complex components for customers worldwide.

| General Characteristics of Materials: | ||||

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium | High | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

EN

EN  CN

CN